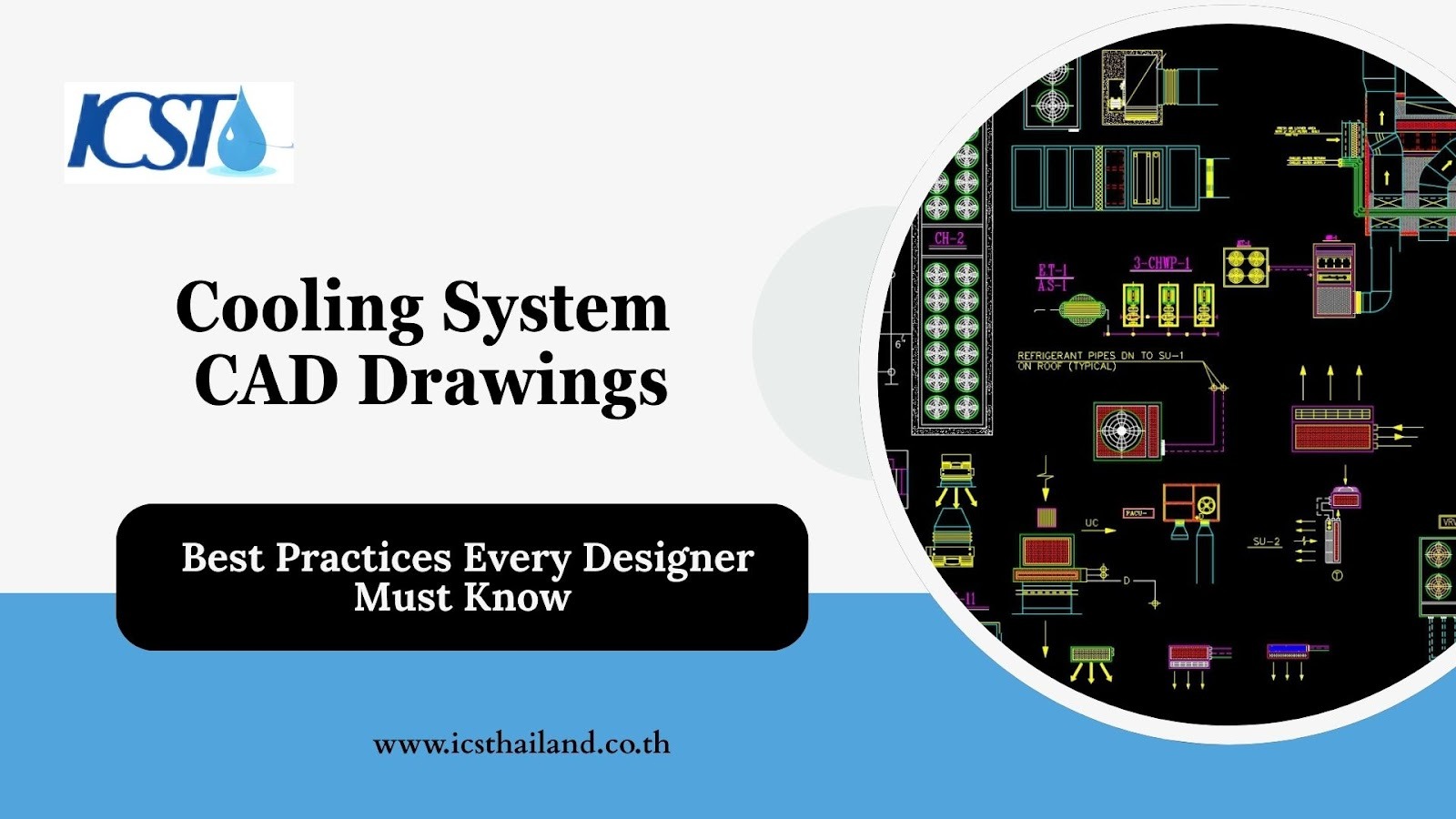

Thermal management is a critical component of modern infrastructure, yet the complexity of designing these systems requires more than just calculation. It demands precise, standardized documentation to ensure that what is designed can be built and maintained effectively.

At the center of this process are cooling system CAD drawings, which serve as the visual language for mechanical, electrical, and plumbing (MEP) engineers.

These technical documents range from simple 2D layouts to complex Building Information Modeling (BIM) data. They facilitate every stage of a project, from the initial concept and spatial coordination to installation and long-term facility maintenance.

Without accurate drawings, projects face costly delays, clashes during construction, and inefficient operation. This guide explores the essential resources, formats, and best practices for utilizing CAD in cooling system design.

Table of Contents

ToggleWhat Are Cooling System CAD Drawings?

Cooling system CAD drawings are digital representations of thermal regulation infrastructure created using Computer-Aided Design software. These drawings define the physical geometry, spatial relationships, and functional logic of equipment such as chillers, cooling towers, pumps, and piping networks. They are the bridge between theoretical thermodynamics and physical reality.

Unlike general sketches, professional CAD drawings offer:

- Precise Data: Includes specific dimensional details, material specifications, and exact connection points.

- System Integration: Coordinates cooling infrastructure with overall HVAC and plant designs.

- Structural Alignment: Ensures mechanical requirements fit within building constraints and electrical capacities.

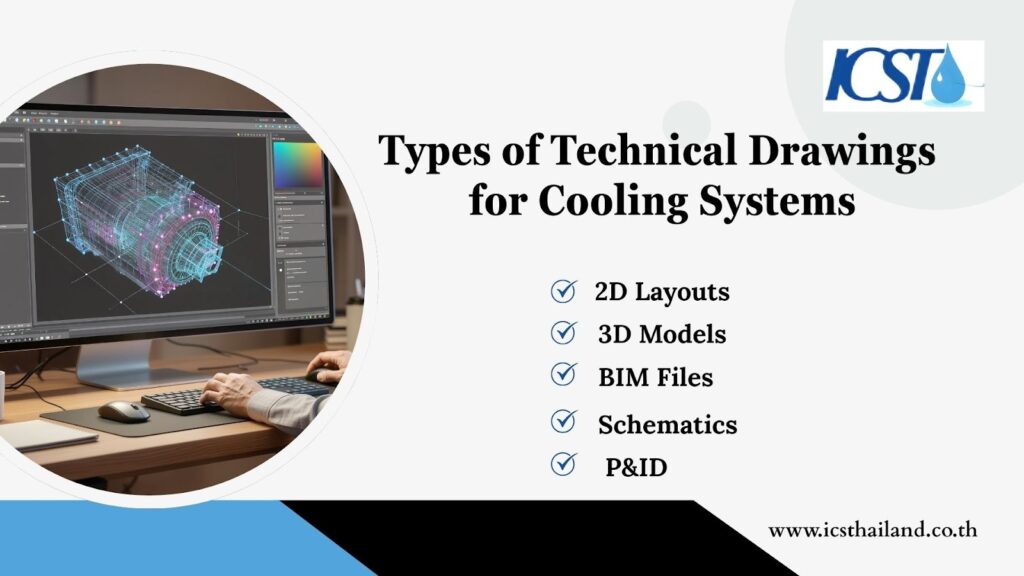

Key Types of Technical Drawings for Cooling Systems

2D Layouts

Two-dimensional layouts remain the industry standard for on-site construction documentation. These drawings flatten complex geometries into readable plans that contractors use for installation.

These layouts provide a top-down or side view of the system:

- Floor Plans: These show the exact location of heavy equipment like chillers and pumps relative to the building grid.

- Elevations: These views are crucial for understanding vertical clearances for ductwork and piping runs.

- Piping Layouts: These detailed drawings illustrate the route of hydronic piping, including supports and valve locations.

3D Models

Parametric 3D models allow engineers to visualize the entire assembly before fabrication begins. Unlike 2D drawings, these models contain depth and volume data, which is essential for tight mechanical rooms.

Using 3D CAD provides distinct advantages in complex environments:

- Spatial Coordination: Engineers can see exactly how components fit together in a congested space.

- Interference Checks: Software can automatically detect if a pipe collides with a structural beam or electrical tray.

- Fabrication Support: Manufacturers use these files to cut and bend metal with high precision.

BIM Files

Building Information Modeling (BIM) files take 3D modeling a step further by embedding data into the geometry. Files such as Revit families or IFC exports contain metadata about the product’s weight, electrical load, and maintenance schedule.

BIM transforms the design process through enhanced collaboration:

- Integration: BIM files allow mechanical designs to live inside a shared architectural model.

- Lifecycle Management: Facility managers use this data to track asset performance after construction is complete.

- Cross-Discipline Coordination: Structural and electrical teams can instantly see how mechanical changes affect their systems.

Schematics

Schematics act as the logical brain of the design rather than a physical map. They represent the flow of fluids and energy through the system without regard for physical scale or location.

Schematic diagrams serve specific communication goals:

- System Logic: They demonstrate how the system functions operationally.

- Component Connectivity: They show the order of equipment, such as a pump feeding into a heat exchanger.

- Design Validation: Engineers use them to verify that the system architecture meets the thermal load requirements.

P&ID (Piping and Instrumentation Diagrams)

P&ID diagrams are specialized schematics that define the piping process and the control instrumentation. In industrial cooling applications, the P&ID is the master document for process safety and control logic.

These diagrams adhere to strict standards to ensure universal readability:

- Instrumentation Symbols: These indicate where sensors, gauges, and actuators are placed.

- Line Types: Different line styles denote process piping, pneumatic signals, or electrical data links.

- Tagging Systems: Every valve and instrument receives a unique identifier for tracking and maintenance.

Where to Find Cooling System CAD Drawing Resources

Finding high-quality CAD assets is a prerequisite for efficient design. Engineers can source system CAD drawings from various online repositories, ranging from open-source community libraries to proprietary manufacturer databases. The choice of source often dictates the accuracy and file compatibility (such as DWG, STEP, or Revit formats) of the asset.

Free CAD Libraries

General CAD libraries offer a vast array of generic components that are useful for preliminary layouts. Platforms like ARCAT and various BIM hosting sites provide free access to blocks and families.

These resources are particularly useful in early design stages:

- Generic Blocks: These allow for space planning without committing to a specific vendor.

- Standard Parts: Items like flanges, elbows, and common valves are readily available.

- Rapid Prototyping: Designers can quickly populate a model to test feasibility.

Manufacturer and Product BIM/CAD Libraries

When precision is required, manufacturer-supplied libraries are the superior choice. Vendors of chillers, cooling towers, and hydronic units provide models that represent their actual products.

Using manufacturer data ensures the design reflects reality:

- Dimensional Accuracy: The model dimensions match the physical unit exactly.

- Connection Points: Inlet and outlet flanges are located precisely where they will be on the site.

- Performance Data: BIM files often include the specific cooling capacity and electrical requirements of the unit.

How to Use Cooling System CAD Drawings in Engineering Workflows

Integrating cooling system CAD drawings into a workflow requires a strategic approach to ensure file performance and accuracy. Whether using AutoCAD, Revit, or SolidWorks, the process starts with importing the correct file type. It’s best practice to clean imported cooling system CAD drawings of unnecessary layers or data that could bloat the main project file.

To maximize efficiency and accuracy when working with these files, follow these core integration practices:

- Coordinate layouts and models: Link 2D layouts with 3D models to ensure changes propagate across all views and prevent spatial errors.

- Maintain consistency: Adhere to strict layering and annotation standards to ensure correct line weights and legible text during export.

- Implement version control: Track iterations carefully to ensure the entire team is working from the most recent version of the system CAD drawings.

How to Choose the Right CAD Format

Selecting the correct file format is not a matter of preference but of project requirements. The decision depends heavily on the stage of the design and the software ecosystem of the project team.

Consider these factors when selecting a format:

- Project Phase: Conceptual designs often rely on 2D DWG files for speed, while construction documentation demands detailed BIM or 3D models.

- Deliverables: If the client requires a digital twin, BIM formats like RVT or IFC are mandatory.

- Editability: Source files like DWG allow for full editing, whereas PDF files are strictly for reference and markups.

- Interoperability: Consider what software your collaborators are using. Neutral formats like STEP or IGES are widely compatible across different CAD programs, preventing translation errors.

- File Size and Performance: Complex 3D models can be large and slow to load. For quick reviews or sharing with non-technical stakeholders, lightweight formats like DWF or 3D PDF are more efficient.

- Data Richness: For manufacturing and operations, you need more than just geometry. Formats like STEP AP242 include Product and Manufacturing Information (PMI), such as tolerances and material specifications, embedded directly in the model.

Integrating P&ID Diagrams and CAD Drawings

The relationship between the P&ID and the physical layout is one of dependency. The P&ID dictates what is connected, while the CAD drawing dictates where it is located. Successful integration requires constant cross-referencing.

Engineers must ensure that every component on the P&ID appears in the physical model. If the P&ID shows an isolation valve before a strainer, the 3D model must reflect that exact sequence. Advanced design software can now link these document types, flagging discrepancies if a valve exists in the schematic but is missing from the layout.

Best Practices for CAD Drawing Management

How do you keep thousands of files organized without losing your mind or your data? Organization is the difference between a smooth project and a chaotic failure, especially in large-scale plant designs.

Here are the standards you must implement:

- Naming Conventions: Use a rigorous file naming structure (e.g., Project-System-Level-Type) to ensure files are searchable.

- Layer Standardization: Adhere to industry standards (like AIA or ISO) for layer names so external consultants can read your drawings.

- Reference Management: Keep external references (XREFs) relative and organized in a dedicated folder structure to prevent broken links.

- Version Control: Implement a strict “Check-In/Check-Out” protocol or a Product Data Management (PDM) system to prevent team members from overwriting each other’s work.

- Master Seed Files: Utilize standardized templates for all new drawings to ensure that units, text styles, and dimension settings remain uniform across the entire project.

- Regular Audit Cycles: Schedule weekly file “clean-ups” to purge unused blocks, layers, and styles, keeping file sizes manageable and reducing software crashes.

Common Challenges & How to Overcome Them

Why does software interoperability remain such a headache for modern engineers? Even when working on specialized projects like cooling system CAD drawings, specific hurdles inevitably slow down the design process and introduce errors.

Consider these solutions to frequent problems:

- Import Failures and Missing Geometry: Sometimes, complex files simply won’t open, or parts of the design go missing when moving between software. To fix this, export your file using a neutral “middle-man” format like STEP or IGES, which most programs can read without losing details.

- Inconsistent Component Families: It’s frustrating when team members use different versions of the same part, leading to errors in the final build. You can overcome this by creating a single “Master Template” that everyone must use, pre-loaded with approved parts that have already been checked for accuracy.

- Discipline Clashes (Parts Overlapping): A common mistake is finishing a design only to realize a pipe is running straight through a structural beam. Prevent this by setting a weekly “Clash Check” where you merge the mechanical and structural models to find and fix these overlapping parts before they reach the construction site.

Conclusion

The success of any cooling project relies on accurate and well-organized documentation, particularly cooling system CAD drawings. These detailed drawings are essential for guiding construction while also ensuring long-term efficiency, safety, and maintainability.

For modern engineers, mastering CAD tools and building a library of trusted resources is crucial. Establishing internal standards and leveraging the right file formats transforms these drawings into valuable engineering assets. By curating high-quality documentation, engineers can streamline workflows, reduce errors, and optimize project outcomes.

This blog highlights the critical role of CAD resources in cooling projects and offers practical advice on creating and managing an effective CAD library to enhance system performance and reliability.

Frequently Asked Questions

What file formats are best for cooling system CAD drawings?

The best format depends on the software. DWG is the standard for 2D AutoCAD work. RVT is standard for Revit BIM environments. STEP or IGES files are best for transferring 3D geometry between different mechanical design programs.

How can I convert 2D CAD to 3D models?

Most modern CAD software allows you to import a 2D DWG as a reference “underlay.” You can then trace over the plan layout and extrude the geometry to create 3D walls, pipes, and equipment.

Where do engineers get BIM files for HVAC systems?

Engineers primarily source these from manufacturer websites (such as Trane, Carrier, or Marley) or from aggregation platforms like BIMobject and ARCAT.

What’s the difference between schematics and P&ID diagrams?

A schematic is a general overview of the system flow. A P&ID is a detailed technical document that includes all piping, valves, instrumentation, and control logic required for construction and operation.

How do I ensure CAD model accuracy for construction?

Always verify the CAD dimensions against the manufacturer’s certified “cut sheets” or PDF submittals. Never assume a downloaded block is 100% accurate without checking it against the official data.