Is your current setup leaving you frustrated with high costs and inefficiency? An Adiabatic Cooling System could be the answer you need. Many traditional cooling systems, from mechanical chillers to open-loop towers, drain budgets and waste resources, falling short on energy efficiency and reducing water and energy consumption. Upgrading to a modern Adiabatic Cooling System addresses these challenges head-on, supporting both your sustainability goals and your bottom line.

There is a clear escape. An adiabatic cooling system provides an energy-efficient, optimized alternative to outdated cooling technology. Adiabatic cooling systems work by leveraging indirect adiabatic cooling and a dual-mode closed-loop design that brings the highest quality performance, dramatically reducing both water consumption and energy use.

This advanced system nearly eliminates chemical water treatment while maximizing savings on operational and maintenance costs. Adiabatic systems are efficient, innovative, and proven to boost cooling capacity in industrial processes.

Table of Contents

ToggleThe Alternative Trap and The Reveal

It is important first to understand the challenges posed by conventional cooling systems. Many plants, data centers, and industrial facilities are trapped between two old options, each with major drawbacks when it comes to water evaporation, energy consumption, and system efficiency.

The Flaws in Traditional Cooling

- Traditional Cooling Towers (Evaporative Cooling): These systems provide cooling by evaporating water into the ambient air stream, which reduces air temperature. However, their open-loop design means high, continuous spray water and chemical use, risking increased maintenance costs and water loss. Open-loop towers require substantial water treatment to manage corrosion and scaling, and evaporated water escapes constantly, diminishing efficiency and ramping up consumption.

- Mechanical Chillers: While chillers are known for precision temperature control, they rely on high-energy compressors. This increases energy consumption and drives up costs. Chillers also use chemical refrigerants, contributing to a higher environmental footprint compared to adiabatic cooling systems.

The Revelation: What Is an Adiabatic Cooling System?

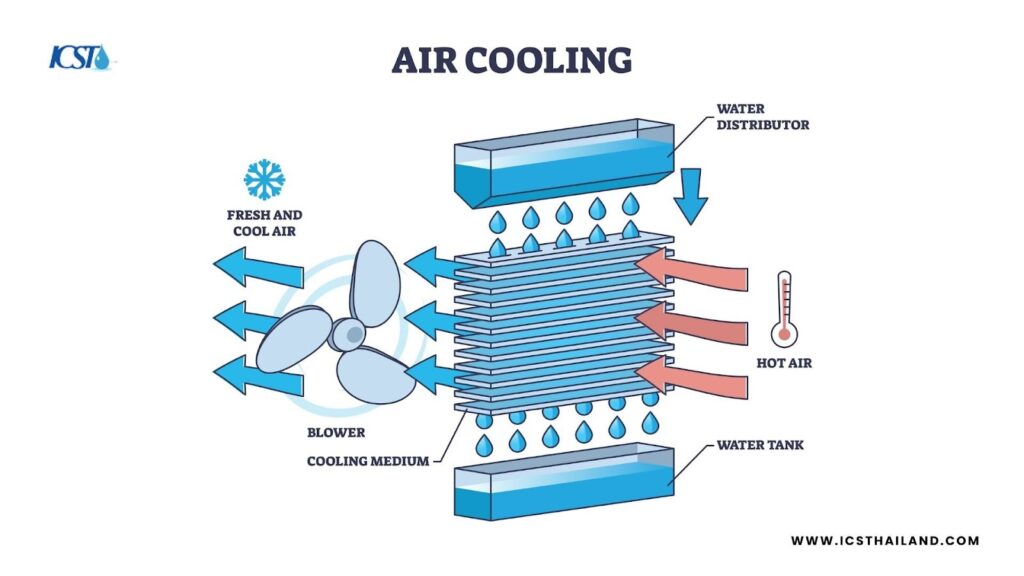

Unlike traditional systems, a modern adiabatic cooling system leverages the principle of reducing air temperature by introducing a controlled water spray or wetted pad, lowering the temperature of incoming air before it passes over a robust heat exchanger.

This indirect adiabatic cooling process pre-cools ambient air and uses it efficiently to cool process fluids without increasing humidity in the facility.

An adiabatic system provides dramatic energy savings due to its innovative closed-loop operation. By only using water spray during high ambient temperature periods, unlike evaporative cooling towers, the system ensures low water consumption and optimized heat transfer, even in dry climates or dry environments.

The Indirect Magic of Adiabatic Cooling Systems Work

The core innovation in modern indirect adiabatic cooling systems is the way they manage airflow and water. Instead of directly evaporating water in the main cooling stream, these systems create a pre-cooled airstream.

The pre-cooled air then passes over a heat exchanger coil, never mixing with the liquid process fluid, which keeps the operation efficient and clean.

Here is how advanced adiabatic cooling systems work:

- Air Intake: Fans draw in warm ambient air.

- Pre-Cooling with Water Spray: Only when needed, spray water mists onto a pad or coil, evaporating water efficiently as the air passes through.

- Indirect Heat Transfer: Cooled air proceeds to the exchanger coil, cooling the fluid inside through a physical barrier of the coil. This prevents any direct water/process contact.

- Closed-Loop System: The now cooled fluid returns through the closed loop for further use in industrial processes and cooling applications.

These heat exchangers, cooling coils, and spray systems are designed for high reliability and low maintenance.

Distinguishing the Types: Direct and Indirect Adiabatic Cooling

- Direct Adiabatic Cooling: Here, air directly passes through a wetted pad or spray system, becoming cooled air but also picking up some humidity. This approach is beneficial for direct applications like plant humidification or agriculture, but not ideal for data centers or electronics where humidity is a risk.

- Indirect Adiabatic Cooling (The Secret Sauce): This system keeps fluid and air separate, reducing humidity concerns while optimizing water and energy consumption.

- Hybrid/Two-Stage Adiabatic Cooling System: The ultimate in flexibility, these dry coolers operate in dry mode during moderate weather, only using adiabatic mode and spray water in periods of high demand. This ensures the system offers low water consumption and superb efficiency across all seasons.

The Key Distinction: Adiabatic vs. Evaporative Cooling

Traditional evaporative cooling systems rely on evaporated water as their primary means of heat dissipation, leading to continuous water loss. Adiabatic cooling, particularly hybrid systems, uses water intermittently to vastly reduce consumption while maintaining or increasing cooling capacity.

In dry environments and industrial settings, this means substantial water reduction without loss of efficiency or system capacity.

The 10 Commandments of Financial Payback

Switching to adiabatic cooling systems is not just an operational upgrade but a strategic investment in efficiency, sustainability, and cost reduction. Facilities can benefit from this new technology across a wide range of applications, delivering savings and superior operation.

10 Core Benefits and Advantages

- Exceptional Energy Efficiency: Energy-efficient adiabatic systems can deliver up to 40 kW of cooling with just 1 kW of electricity, outpacing older cooling systems.

- Massive Water Savings: Water consumption can be cut by as much as 95%, especially in dry climates, thanks to intermittent spray operation.

- Chemical-Free Operation: The closed-loop adiabatic system minimizes reliance on water treatment and eliminates continuous chemical use.

- Performance Optimization: Advanced controls and efficient operation drive both higher ROI and compliance with environmental standards.

- Lower Maintenance Costs: Fewer moving parts and reduced scaling/corrosion risk mean more uptime and lower costs.

- Rapid Return on Investment: Energy savings, water reduction, and chemical elimination combine for payback in under two years.

- Sustainable Technology: Minimal environmental impact, water used is non-toxic, and there’s no harmful refrigerant use.

- Flexible Operation: Systems automatically switch between dry mode and adiabatic mode, using water only when needed based on incoming air conditions.

- Reduced Equipment Wear: Closed system design limits exposure of plant and machinery to humidity, water, or contaminants.

- Scalability: Highest quality adiabatic coolers adapt seamlessly in small, medium, or large-scale industrial processes.

The Cost Factor Showdown

| Cost Factor | Traditional Cooling Towers | Adiabatic Systems (Hybrid) | Savings & Advantage |

| Water Usage | High (continuous blowdown and evaporating water) | Very Low (intermittent water spray) | Up to 95% reduction in water consumption |

| Chemical Treatment | Required for scale/corrosion/wet operation | Not required in closed loop | Eliminates recurring water treatment costs |

| Energy Consumption | High for pumps/fans and chillers | Low (dry cooler plus adiabatic mode when hot) | More energy efficient and dramatic energy savings |

Mastering Strategy and Application

Adiabatic cooling systems excel in diverse applications, thanks to their high-efficiency heat exchanger design and adaptive operation.

Where Adiabatic Systems Thrive

Adiabatic cooling offers the best results for any facility aiming to reduce water and energy consumption, maintenance costs, and environmental impact. These systems are ideal for:

- Data Centers: Prioritize ultra-low PUE and WUE by optimizing energy and water.

- Manufacturing Plants: Enhance process cooling for plastics, automotive, or heavy industry.

- Commercial HVAC: Improve comfort cooling in airports, offices, or retail environments.

Addressing Design Challenges

One practical consideration for adiabatic cooling system installation is the physical footprint. Units often require greater coil surface area than traditional models. Smart solutions, such as mounting the unit above ground or configuring it for wall installation, ensure the highest quality fit for your plant or facility.

AI and Mastering Optimization

AI and mastering optimization refer to the integration of artificial intelligence to enhance the performance and efficiency of adiabatic cooling systems. By leveraging predictive analytics, AI monitors real-time data such as ambient temperature, humidity, and system load to forecast cooling needs.

This ensures precise activation of the adiabatic mode, minimizing water and energy consumption. Additionally, AI-driven systems detect early signs of maintenance issues, such as scaling or clogging, preventing efficiency losses. This intelligent approach transforms adiabatic systems into proactive, highly efficient solutions, maximizing ROI and operational reliability.

Optimization is the key to unlocking full benefits from adiabatic systems in both wet and dry operation.

AI-Driven Adiabatic Cooling

- Predictive Analytics: AI monitors changes in ambient air temperature, humidity, and pressure, making the system more efficient by pre-emptively switching from dry cooler to adiabatic mode.

- Precise Water Usage: AI algorithms minimize spray system operation, deploying water only at the evaporative tipping point, maximizing efficiency and reducing water consumption.

- Preventative Maintenance: Sensors detect drops in performance, such as a clogged pad or decreased air flow, alerting plant managers before major efficiency loss.

These advantages transform adiabatic systems into the most advanced, energy-efficient cooling systems on the market.

Conclusion:

The adiabatic cooling system represents the pinnacle of efficient, reliable, and sustainable cooling technology, a true leap beyond traditional chillers, wet cooling towers, or other outdated approaches. Modern facilities need to focus on reducing water and energy consumption, installation costs, and system complexity.

Break free from the drawbacks of evaporative cooling, high humidity, and costly maintenance. The Adiabatic Cooling System offers powerful energy savings, lower water consumption, and reliable operation, meeting today’s efficiency and sustainability demands.

Do not settle for outdated solutions when your facility deserves the advanced technology of an Adiabatic Cooling System. Take the first step toward International Cooling Solutions, unlocking the complete benefits of the Adiabatic Cooling System for your business.

Frequently Asked Questions

Why is it called adiabatic cooling?

It is called adiabatic cooling because the process involves reducing the temperature of the air without exchanging heat with the surroundings. This occurs as air expands and loses energy internally.

What is meant by an adiabatic system?

An adiabatic system is a thermodynamic system where no heat is transferred in or out of the system during a process. Energy changes occur only through work or internal transformations.

What is adiabatic cooling in the atmosphere?

Adiabatic cooling in the atmosphere happens when air rises, expands due to lower pressure at higher altitudes, and cools without gaining or losing heat to its surroundings.

Which process causes adiabatic cooling?

Adiabatic cooling is caused by the expansion of air as it moves to areas of lower pressure, such as when air rises in the atmosphere or flows through a system designed for cooling.