Industrial cooling systems are the circulatory system of many manufacturing and processing facilities. When they fail, the impact is immediate and severe. Production halts, expensive machinery risks overheating, and safety hazards spike. In these high-pressure moments, panic is the enemy and protocol is the solution.

This guide outlines a structured approach to cooling system emergency repair, moving beyond routine maintenance into the critical actions required when failure occurs. By establishing clear roles, prioritizing safety, and understanding repair logic, facility managers can minimize downtime and protect their assets.

Table of Contents

ToggleWhy Cooling System Emergency Repair Matters

Routine maintenance is about prevention; emergency repair is about damage control. The stakes are entirely different. A scheduled filter change doesn’t halt the assembly line, but a catastrophic pump failure does.

Here’s why a swift, well-planned emergency response is crucial:

- Financial Impact: The cost of downtime goes far beyond the repair itself. Production losses can amount to thousands of dollars for every minute a system is offline.

- Asset Damage: Uncontrolled heat can lead to severe equipment damage, such as warped components or hazardous chemical reactions in process fluids.

- Safety Risks: In the rush of an emergency, there’s a higher temptation to take shortcuts, significantly increasing the risk of workplace injuries.

This protocol provides a clear roadmap to manage the crisis effectively, bridging the gap between system failure and safe restoration. It outlines how to stabilize the situation, assess the damage, and execute a secure repair strategy.

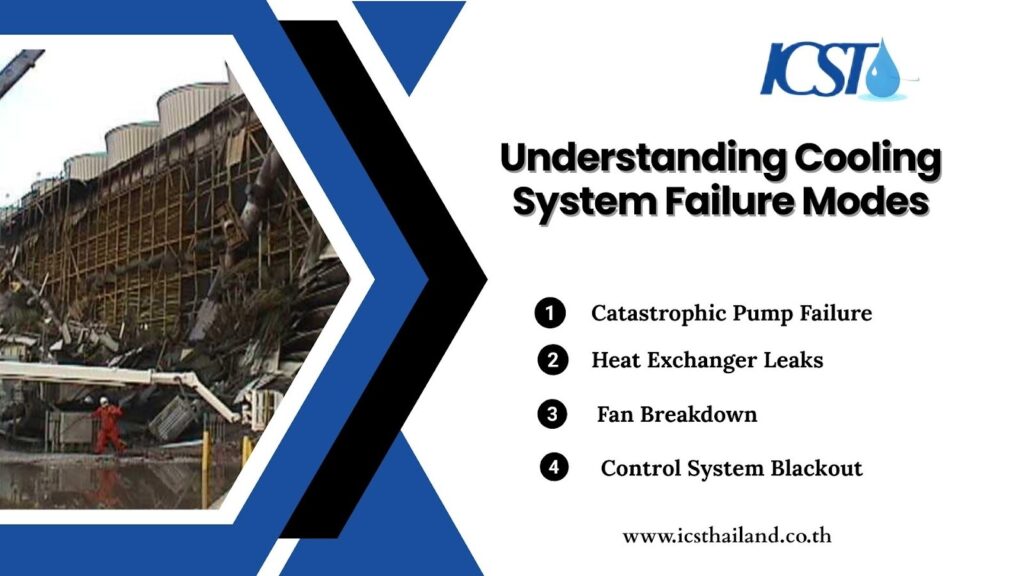

Understanding Cooling System Failure Modes

Recognizing the difference between a minor glitch and a full-blown emergency is the first step in effective management. Not all alarms require an all-hands-on-deck response, but hesitating during a critical failure can be disastrous.

Common failure modes that trigger a cooling system emergency repair include:

- Catastrophic Pump Failure: Sudden loss of flow due to motor burnout, seal rupture, or impeller breakage.

- Heat Exchanger Leaks: Mixing of process fluids with cooling water, leading to contamination or environmental hazards.

- Fan Breakdown: Loss of heat rejection capacity, causing rapid temperature spikes in cooling towers.

- Control System Blackout: Loss of visibility and automated regulation.

Facility teams must distinguish between early warning signs (like increased vibration or minor noise) and actual emergency states. An emergency is declared when safety is compromised or when critical production thresholds are breached.

Rapid Response Team: Roles & Responsibilities

Chaos often follows failure. To counter this, a rapid response team must be predefined. This team shouldn’t be figuring out their roles while alarms are blaring; they should be executing a drilled plan.

- Lead Technician: The Incident Commander. They direct resources, make the final call on repair vs. shut down, and manage the overall timeline.

- Electrical Specialist: Responsible for isolating power, diagnosing control faults, and ensuring electrical safety during the repair.

- Mechanical Support: Handles the physical repair work, rigging, and parts replacement.

- Safety Officer: Their sole focus is on monitoring hazards. They have the authority to stop work immediately if a protocol is violated.

Communication is vital. The rapid response team should use dedicated radio channels or communication apps to keep clear of general plant chatter, following a strict incident command sequence where all updates flow through the Lead Technician.

Step-by-Step Emergency Repair Protocol

Speed is important, but order is essential. Jumping straight to “fixing” without securing the area leads to accidents. The prioritization process should always follow this order: Safety, Containment, Temporary Fix, Permanent Repair.

Step 1 | Isolate and Secure the Failure Area

Before a wrench touches a bolt, energy must be controlled. This involves strict Lockout/Tagout (LOTO) procedures for all energy sources—electrical, hydraulic, and thermal. Hazardous sections must be physically cordoned off to prevent non-essential personnel from entering the danger zone.

Step 2 | Assess Safety and Hazard Exposure

After isolating the failure area, evaluate the immediate environment for hazards. The Safety Officer must conduct a rapid risk assessment to ensure it’s safe. Only then can the mechanical team approach the equipment for diagnosis.

Key hazard checks include:

- Atmospheric Hazards: Are there any refrigerant or chemical leaks that could pose a breathing risk?

- Physical Hazards: Check for slip-and-fall risks from water, oil, or glycol spills.

- Energy Hazards: Is nearby equipment radiating dangerous levels of heat or other forms of energy?

Step 3 | Check for Damage and Find Out What Needs Fixing

Once the area is confirmed safe, the Lead Technician begins the diagnostic process to pinpoint the problem’s root cause. This involves a thorough inspection and, if possible, functional testing.

The findings will dictate the necessary repair, from a quick part replacement to a more extensive overhaul. Key diagnostic steps include:

- Visual Inspection: Carefully examining the equipment for any visible signs of damage, wear and tear, or leaks.

- Functional Testing: Cautiously operating the equipment (if safe) to observe its performance and identify malfunctions.

- Root Cause Analysis: Using the information gathered to determine the underlying issue, which informs the complexity and scope of the required repair.

Spare Parts Strategy for Emergency Repairs

You cannot repair what you don’t have. A well-stocked spare parts kit is the difference between a two-hour delay and a three-day shutdown.

Essentials for your spare parts kit should include:

- Replacement belts and couplings.

- Critical sensors (temperature, pressure, flow).

- Pump seals and gasket kits.

- Standardized motors or variable frequency drives (VFDs).

Inventory management is key. Using a part from the emergency kit for routine maintenance without replacing it immediately defeats the purpose. Selection should be data-driven; review past failure logs to identify which components fail most frequently and ensure those are always on hand.

Temporary Fixes and Workarounds (Safety First)

In a crisis, a permanent repair might not be immediately possible. Temporary fixes can bridge the gap, but they must be scrutinized heavily.

Approved workarounds might include installing bypass valves to route flow around a damaged exchanger or using temporary couplings to limp a pump along at reduced capacity. However, temporary fixes are strictly forbidden if they compromise safety interlocks or pressure relief systems.

Any temporary measure must be documented, labeled clearly on the machine, and given a strict expiration date for when the permanent repair will occur.

Contractor Escalation & 24/7 Service Protocols

If a failure goes beyond your team’s expertise or tools, bringing in contractors is essential. Be prepared with clear escalation requests and service agreements to ensure quick resolutions.

Key Tips for Contractor Escalation:

- Be specific in your request: Include equipment model, failure details, and urgency level.

- Set up 24/7 service agreements: Partner with specialized cooling tower and chiller contractors in advance.

- Consider retainer models: These often guarantee faster response times (e.g., within 4 hours) during critical moments like heatwaves.

Communication and Incident Reporting

Information vacuums can lead to confusion and panic, especially in high-pressure situations. Establishing a real-time communication cadence ensures everyone stays aligned and informed.

For example, the Lead Technician can update the Plant Manager every 30 minutes on progress, challenges, or any unexpected issues. Use simple incident logging templates to record:

- Time of failure.

- Actions taken.

- Current status.

- Estimated time to recovery (ETR).

Notifications must reach Operations (to manage production schedules), Safety (to manage risk), and Management (to manage resources).

Safety Considerations During Emergency Repair

Emergency repairs often happen in less-than-ideal conditions—poor lighting, extreme heat, or tight spaces. To ensure you’re prepared, always have the right tools on hand, such as a high-powered flashlight, heat-resistant gloves, and compact equipment designed for confined areas.

- PPE: Ensure all team members have gear specific to the hazard (e.g., chemical-resistant gloves for glycol leaks).

- LOTO Reinforcement: Verify locks are secure, and keys are managed by the personnel doing the work.

- Fall Protection: If the cooling system emergency repair involves cooling towers on rooftops, fall protection harnesses and anchor points are non-negotiable.

- Electrical Safety: Assume all circuits are live until tested and verified.

Conclusion & Safety Reminder

A cooling system emergency repair is a high-stakes event that demands a calm, calculated response. This guide outlined the essential protocol, starting with the immediate actions for your Rapid Response Team, including their specific roles and responsibilities.

We covered the importance of a well-stocked spare parts inventory and defined clear criteria for when to handle repairs in-house versus escalating to a contractor. Key considerations include the approval process for temporary fixes and the absolute priority of safety over speed.

Equip your facility with a certified emergency repair protocol today. Contact ICST for rapid response planning, 24/7 service arrangements, and customized emergency repair readiness support.

Frequently Asked Questions

How quickly should an emergency response begin?

Initial response should start within 10–15 minutes of alarm activation. Early isolation and assessment significantly reduce downtime and prevent secondary damage.

What is a cooling system emergency repair?

A cooling system emergency repair is required when a failure:

- Creates a safety risk

- Stops critical production

- Causes rapid temperature rise or equipment damage

Examples include pump failure, fan breakdown, or control system loss.

What spare parts are essential for cooling system emergency repair?

Essential spare parts include pump seals, motors, fan belts, couplings, and critical sensors. Keeping these items in stock minimizes downtime caused by long lead times during emergency situations.

What safety measures are essential during emergency repair?

Use proper PPE (gloves, helmets, chemical-resistant gear), verify all energy sources are isolated, implement fall protection for elevated systems, and maintain strict communication. Safety is the top priority before, during, and after repair.