In any industrial facility, cooling systems are critical for maintaining operational stability and ensuring safe working temperatures. However, unexpected events like fires, major leaks, or power outages require immediate action from operators. An emergency stop is not the same as a planned maintenance halt; it must be executed quickly, accurately, and with a primary focus on safety.

While a routine shutdown focuses on preserving machine longevity through gradual cooling, an ESD prioritizes the immediate protection of human life and the containment of hazardous conditions. Fires, chemical spills, or uncontrolled vibrations demand rapid intervention to prevent disaster.

This guide outlines the critical steps and principles necessary to execute a safe and effective cooling system emergency shutdown, ensuring personnel safety and minimizing equipment damage.

Table of Contents

ToggleCore Principles of Cooling System Emergency Shutdown

An effective emergency response relies on a hierarchy of priorities. Operators must understand that saving a piece of equipment is never worth risking a life.

When executing an emergency shutdown, adhere to these fundamental principles:

- Prioritize personnel safety: The well-being of staff and emergency responders always comes first.

- Prevent equipment damage: While secondary to life safety, proper procedures aim to stop machinery without causing catastrophic mechanical failure.

- Protect process continuity: Where safe, isolate only the affected sections to maintain critical upstream or downstream operations.

- Capture root cause: Secure data and evidence immediately to understand why the event occurred and prevent recurrence.

- Align with regulations: Ensure all actions comply with OSHA, NFPA, and local safety codes to maintain legal and operational standards.

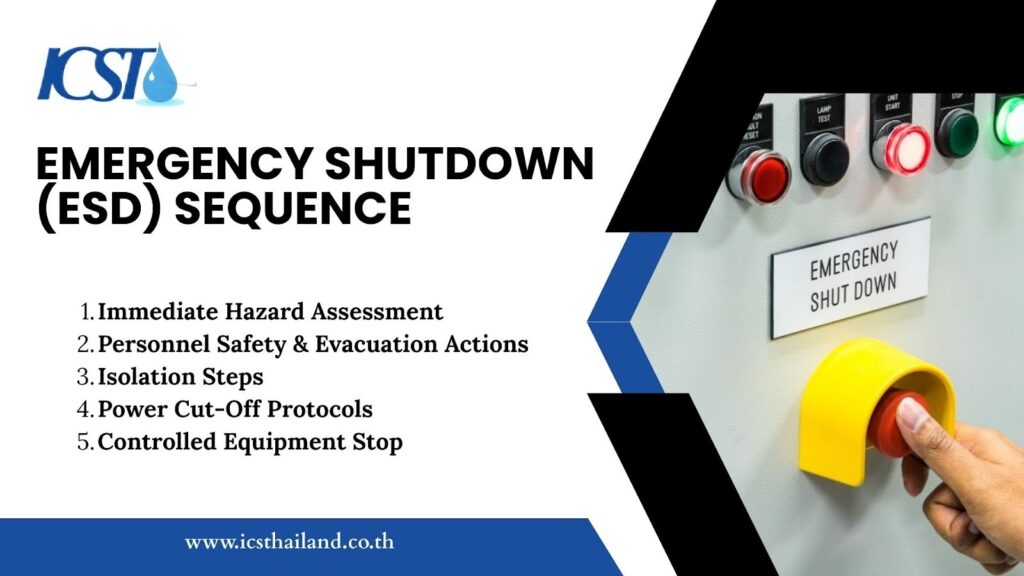

Emergency Shutdown (ESD) Sequence | Step-by-Step Procedures

Chaos often accompanies emergencies, which makes a predefined sequence vital. A clear ESD sequence ensures every team member knows their specific role and responsibility, reducing confusion when seconds count.

Step 1 | Immediate Hazard Assessment

Before rushing to a control panel, the operator must understand the threat. Identifying the source determines the correct response strategy.

Assess the situation rapidly to determine the nature of the emergency:

- Identify the cause: Determine if the trigger is a fire, massive chemical leak, or severe electrical fault.

- Initiate alarm: Activate the facility-wide alarm system immediately to alert all personnel.

- Alert the team: Communicate the specific location and nature of the hazard to the control room and emergency response team.

Step 2 | Personnel Safety & Evacuation Actions

Once the alarm sounds, the focus shifts to moving people out of harm’s way. Personnel safety is the non-negotiable top priority in any ESD sequence.

Execute these safety measures immediately:

- Evacuate affected areas: Direct all non-essential personnel to designated muster points away from the hazard zone.

- Enforce PPE usage: Ensure all responders wear appropriate Personal Protective Equipment (PPE) before entering or remaining in critical zones.

- Initiate Lockout/Tagout: Begin the mental preparation for isolation, ensuring no one re-energizes equipment during the crisis.

Step 3 | Isolation Steps

Stopping the flow of energy and fluids prevents the escalation of the emergency. Isolation steps must be methodical to prevent cross-contamination or pressure buildups.

Follow these procedures to isolate the system effectively:

- Isolate water feed: Close main supply valves to stop water flow and prevent flooding or chemical dispersion.

- Engage hydraulic isolation: Shut off hydraulic pumps and close bypass valves to depressurize the system.

- Isolate air intake/exhaust: Close dampers and shut down fans to starve fires of oxygen or prevent fume spread.

- Isolate chemical systems: shut off dosing pumps and close containment valves to prevent hazardous spills.

Step 4 | Power Cut-Off Protocols

Electrical energy fuels motors, pumps, and fans. Cutting power stops the mechanical energy that drives the system, but it must be done safely to avoid arc flash or equipment surges.

Implement these power cut-off protocols strictly:

- De-energize starter panels: Switch off control power at the local starter panels to stop motor commands.

- Use Main Disconnects / E-Stop: Hit the Emergency Stop (E-Stop) button or throw the main disconnect switch for immediate total power loss.

- Execute VFD/MCC safe stop: Follow specific procedures for Variable Frequency Drives (VFDs) and Motor Control Centers (MCCs) to discharge stored energy safely.

Step 5 | Controlled Equipment Stop

Slamming a system to a halt can cause mechanical shock. Even in an emergency, a controlled stop helps protect the asset if the immediate threat allows for milliseconds of deceleration.

Execute controlled stops for major machinery:

- Stop fans, pumps, compressors: Sequentially shut down large rotating equipment to balance system pressure drop.

- Avoid mechanical damage: Use braking resistors or soft-stop features if accessible to prevent shaft shearing or coupling failure.

Equipment Protection Measures During ESD

While safety is paramount during a cooling system emergency shutdown, preserving multimillion-dollar infrastructure is also critical for a swift facility recovery. Equipment protection focuses on mitigating the physical stress caused by a sudden stop.

Consider these factors to safeguard assets during a shutdown:

- Prevent thermal shock: Avoid rapid temperature changes that can crack heat exchanger plates or tubes.

- Avoid water hammer: Close valves slowly where possible to prevent pressure waves that rupture pipes.

- Protect bearings and gearboxes: Ensure auxiliary oil pumps run if main power remains available to lubricate coasting shafts.

- Ensure safe lubrication: Purge corrosive gases or fluids from lines if they pose a stagnant corrosion risk.

Communication Protocol & Incident Control

Information flow is as critical as fluid flow. Clear communication ensures everyone, from the floor operator to the plant manager, operates with the same facts.

Establish a rigid communication structure:

- Inform key stakeholders: Notify the shift supervisor, safety officer, and control room operators immediately.

- Log the timeline: Record the exact start time of the incident and key data points like pressure and temperature readings.

- Follow the communication tree: Adhere to the established chain of command to ensure accountability and prevent rumor spread.

Lockout/Tagout (LOTO) Considerations

An emergency shutdown is only the first step; equipment must be verified safe to touch before work begins. Lockout/Tagout (LOTO) ensures that machines are completely de-energized, preventing accidental startups and protecting workers from harm. Always follow proper LOTO procedures to maintain a safe work environment.

Apply LOTO principles rigorously:

- Understand critical importance: Recognize that LOTO prevents accidental startup while responders investigate the emergency.

- Follow LOTO sequence: Identify energy sources, notify affected employees, shut down, isolate, lock, and tag.

- Verify zero energy: Test the start button and use meters to confirm electricity, pressure, and thermal energy are dissipated.

Safety & Compliance Checkpoints

Regulatory bodies require clear actions during emergencies to ensure compliance and safety. Following these protocols not only protects the company from liability but also safeguards employees and assets. Regular training and audits can help maintain these safety standards effectively.

Verify compliance with these standards:

- Check personal safety: Confirm all personnel are accounted for, and exclusion zones are established.

- Reference code compliance: Ensure actions align with NFPA 70E, OSHA 1910.147, and local fire codes.

- Maintain documentation: Keep accurate records of the event to satisfy regulatory reporting requirements.

Initial Inspection & Verification After Shutdown

Once the immediate danger passes, the recovery phase begins. Do not rush to restart; a thorough inspection is crucial to prevent a secondary emergency. Focus on identifying the root cause of the shutdown to ensure a safe and stable return to operations.

This methodical approach will prevent repeat incidents and protect both personnel and equipment. Conduct a detailed post-shutdown assessment:

- Perform visual inspections: Look for scorch marks, leaked fluids, or physical deformation of tanks and pipes.

- Check for leaks: Walk the lines to identify compromised seals or ruptured expansion joints.

- Release pressure safely: Bleed off any trapped pressure in lines before opening inspection hatches.

- Confirm electrical isolation: Re-verify that power remains off before any physical contact with wires or terminals.

Returning to Service | Safe Restart Procedures

Bringing a cooling system back online after an emergency shutdown (ESD) is a critical phase that requires patience and precision. A systematic restart is essential to prevent common post-shutdown issues like water hammer, thermal stress, and electrical overloads.

Rushing the process can lead to equipment damage or another immediate shutdown, so a methodical approach is key. Follow this stepwise approach to resume operations:

- Follow the bring-up procedure: Use a written checklist to bring subsystems online in the correct order.

- Verify isolation removal: Remove LOTO locks and tags only after confirming the system is intact and clear of personnel.

- Energize slowly: Introduce power and fluids gradually to monitor for leaks or vibration.

- Run functional tests: Test critical safety interlocks and alarms before committing to full production load.

Preventing Future Emergencies | Continuous Improvement

An emergency is a valuable learning opportunity to identify weaknesses. Analyze the data gathered to improve response processes, enhance staff training, and strengthen the facility’s infrastructure against future risks. Proactive measures now can save time, money, and lives later.

Implement these continuous improvement strategies:

- Hold lessons learned meetings: Gather the team to discuss what went well and where the ESD sequence failed.

- Adjust SOPs: Update Standard Operating Procedures (SOPs) based on real-world data from the incident.

- Conduct training and drills: Schedule regular simulations to build muscle memory for the next cooling system emergency shutdown.

Conclusion

When a cooling system fails, a swift and well-executed emergency shutdown (ESD) is critical. This process involves safely isolating the equipment, depressurizing the system, and purging any hazardous materials to protect both personnel and assets. Key steps include immediate shutdown, clear communication, isolating the system, and a careful restart process only after the issue is resolved.

Analyzing every incident is a vital learning opportunity. Use data from emergencies to refine your Standard Operating Procedures (SOPs), enhance staff training with regular drills, and strengthen your facility’s infrastructure. A proactive approach to safety and continuous improvement of your cooling system emergency shutdown plan can save time, money, and lives.

Is your facility prepared for a cooling system emergency? Contact ICST today for expert risk assessments and customized ESD planning to ensure your team is ready.

Frequently Asked Questions

What is a cooling system emergency shutdown (ESD)?

A cooling system ESD is an immediate stop procedure used during critical events like fires, major leaks, or electrical faults. It prioritizes personnel safety and hazard containment over normal equipment operation.

When should an emergency shutdown be initiated?

An ESD should be triggered when there is an immediate risk to human safety, equipment integrity, or the facility, such as fire, uncontrolled vibration, or chemical leakage.

What triggers a cooling system emergency shutdown?

A cooling system ESD is triggered by life-threatening conditions such as fire, major leaks, electrical faults, or uncontrolled vibration. These events require immediate action to prevent injury and catastrophic damage.

Why is personnel safety the top priority during an ESD?

Equipment can be repaired, but injuries and fatalities cannot. ESD procedures are designed first to protect people, then to contain hazards and prevent escalation.

What are the most common ESD failures in cooling systems?

Common failures include incomplete isolation, poor communication, skipped LOTO steps, and rushed restarts. These errors often cause repeat incidents.