Cooling towers are vital components of modern industry, yet they harbor hazards that remain hidden to the untrained eye. Unlike the obvious dangers of heavy construction machinery, the risks within a cooling system are often silent and invisible until an accident occurs.

Bacterial growth like Legionella, corrosive treatment chemicals, and slippery surfaces create a complex safety landscape that demands rigorous preparation. This cooling tower PPE guide aims to equip safety managers and technicians with the knowledge required to protect their teams effectively.

This guide serves as a comprehensive resource for selecting and maintaining the right personal protective equipment (PPE). We will examine specific hazards, break down necessary gear from head to toe, and provide actionable checklists for daily tasks.

Table of Contents

ToggleCooling Tower Hazards That Require PPE

Cooling towers present a unique convergence of chemical, biological, and physical risks. Workers often face multiple threats at once, making comprehensive protection essential. A thorough understanding of these hazards is crucial, and the Cooling Tower PPE Guide can help you select the right equipment to ensure safety on the job.

Technicians must prepare for a variety of dangerous scenarios during routine maintenance. Are your workers ready to face these specific threats?

- Chemical Exposure: Strong biocides, corrosion inhibitors, and scale preventatives can cause severe burns or respiratory damage.

- Electrical Shock Risk: High-voltage pumps and fans operate in wet environments, increasing the potential for electrocution.

- Rotating Machinery: Moving parts like fans, drive shafts, belts, and pulleys can catch loose clothing or limbs.

- Falls from Heights: Accessing the top of towers or drift eliminators often places workers at dangerous elevations.

- Confined Space Entry: Basins and sumps are often classified as confined spaces with poor ventilation.

- Slip Hazards: Water, slime, and algae accumulation make walking surfaces treacherous.

Hard Hats: Your First Line of Defense Against Head Injuries

Head injuries are among the most debilitating accidents in industrial settings. In a cooling tower environment, risks come from falling tools dropped by colleagues working at heights or accidental impact with low-hanging structural beams.

Selecting the right hard hat involves more than just picking a color; it requires adherence to strict safety standards. Consider these factors when outfitting your team:

- ANSI/OSHA Requirements: Ensure all helmets meet ANSI/ISEA Z89.1 standards for industrial head protection.

- Impact Protection: Type I helmets protect only from top blows, while Type II helmets offer protection from top, front, back, and side impacts.

- Class Selection: Class E (Electrical) helmets reduce danger from high-voltage conductors, which is essential near tower pumps.

- Maintenance: Inspect shells for cracks or UV damage daily and replace suspensions annually.

Eye & Face Protection: Goggles and Face Shields

The chemical treatments used in cooling water systems are highly aggressive and can pose serious safety risks. A single splash of concentrated sulfuric acid or sodium hypochlorite could lead to permanent blindness.

That’s why following a comprehensive Cooling Tower PPE Guide is essential to ensure workers are properly equipped to handle these hazardous environments safely.

Why do safety experts recommend specific types of eyewear for chemical handling?

- Safety Glasses vs. Goggles: Goggles provide a full seal around the eyes, preventing liquid entry from the sides or bottom, unlike open safety glasses.

- Face Shields: Technicians should wear face shields over goggles when pouring chemicals to protect the entire face.

- Anti-Fog Coatings: Humid tower environments cause lenses to fog quickly; specialized coatings maintain visibility.

- Chemical Resistance: Ensure lens and frame materials resist degradation from the specific biocides in use.

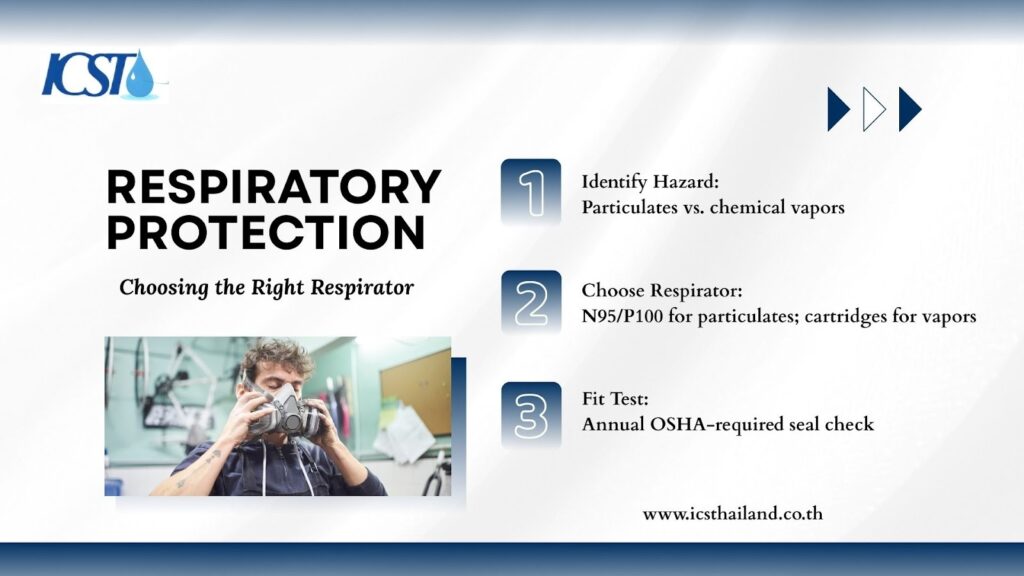

Respiratory Protection: Choosing the Right Respirator

Respiratory hazards in cooling towers include both chemical vapors and biological aerosols. The mist drifting from a tower can carry Legionella bacteria, while pump rooms may contain concentrated chemical fumes.

Engineering controls provide the first line of defense, but as this Cooling Tower PPE Guide highlights, personal respiratory gear remains critical. Follow these guidelines to ensure workers breathe safely:

- Hazard Identification: Determine if the risk is particulate (bacteria/mist) or vapor (acid fumes/chlorine).

- Respirator Types: Use N95 or P100 masks for particulates and biological aerosols; use cartridge respirators for chemical vapors.

- Fit Testing: OSHA requires annual fit testing to verify that the mask forms a tight seal on the wearer’s face.

Training: Workers must understand how to inspect seals and when to change cartridges.

Hand Protection: Chemical Gloves and Cut-Resistant Gloves

Hands are the primary tools of any technician, making them highly susceptible to injury. Cleaning basins exposes skin to harsh bacteria, while mechanical repairs involve sharp metal edges and heavy tools. A single pair of gloves rarely suffices for all tasks.

To prevent dermatitis, burns, and lacerations, you must match the glove material to the specific job. Do not assume one type fits all applications:

- Biocide Handling: Use heavy-duty, chemical-resistant gloves (nitrile, neoprene, or PVC) when handling water treatment chemicals.

- Mechanical Work: Wear chemical gloves with cut-resistant liners or dedicated leather gloves for dry mechanical repairs.

- Chemical Compatibility: Consult safety data sheets (SDS) to ensure the glove material resists the specific chemicals in use.

- Inspection Protocol: Check for pinholes or tears before every use by inflating the glove with air.

Hearing Protection: Noise Hazards and Protection Devices

Cooling towers are notoriously loud, making noise management a critical part of any Cooling Tower PPE Guide. Large fans, splashing water, and motor pumps generate continuous noise, and prolonged exposure to levels above 85 dB can lead to permanent hearing loss.

Effective hearing protection must reduce noise exposure without isolating the worker completely. Here is how to select the right device:

- Noise Sources: Identify high-noise zones near gearboxes, fans, and circulation pumps.

- Decibel Thresholds: OSHA mandates protection when noise exposure equals or exceeds an 8-hour time-weighted average of 85 decibels.

- Earplugs vs. Earmuffs: Earplugs offer convenience for tight spaces, while earmuffs are easier to remove and replace frequently.

- Communication: Consider electronic earmuffs that block harmful noise but allow voice communication.

Foot Protection: Non-Slip Boots and Safety Toe Requirements

The environment around a cooling tower is inherently wet and slippery. Algae growth on basin floors creates surfaces as slick as ice, leading to severe slip-and-fall accidents. Furthermore, heavy pipes and motors pose a crushing hazard to feet.

Standard work boots often lack the traction required for these specific conditions. Managers should enforce strict footwear policies that prioritize grip and impact resistance:

- Traction Focus: Non-slip boots with specialized rubber outsoles provide essential grip on wet, algae-covered surfaces.

- Safety Toe Cap: Steel or composite toes protect against crushing injuries from dropped tools or heavy equipment.

- Puncture Resistance: Sturdy soles prevent nails or sharp debris from penetrating the foot during outdoor maintenance.

- Electrical Hazard Rating: EH-rated footwear offers secondary protection against incidental contact with electrical circuits.

Fall Protection: Safety Harnesses and Fall Arrest Systems

Maintenance tasks often require workers to climb ladders to reach the fan deck or drift eliminators. Falls from these heights are frequently fatal. When engineering controls like guardrails are not feasible or are removed for access, active fall protection becomes mandatory.

A safety harness serves as the worker’s lifeline when operating at elevation. Ensure your fall protection strategy includes these critical elements:

- Height Requirement: OSHA generally requires fall protection for general industry work at heights of four feet or higher.

- Harness Types: Full-body harnesses distribute impact forces; positioning harnesses hold a worker in place for hands-free work.

- Anchor Points: Identify certified anchor points capable of supporting 5,000 pounds per attached worker.

- Rescue Plan: Do not deploy fall arrest systems without a documented plan to retrieve a suspended worker quickly.

Additional PPE Considerations

While the major categories cover most risks, specific conditions require supplemental gear. Outdoor towers expose workers to weather extremes, and high-traffic areas pose visibility risks. Comprehensive safety plans address these environmental factors.

Beyond standard gear, consider these items to round out your safety inventory:

- Protective Clothing: Chemical-resistant suits or aprons prevent body burns during liquid transfer.

- High-Visibility Apparel: Vests ensure technicians are visible to forklift operators or vehicles near the tower.

- Heat Stress Gear: Cooling vests and hydration packs help prevent heat exhaustion during summer maintenance.

- Layering: Workers should wear moisture-wicking layers under suits to manage sweat and temperature.

Task-Based PPE Checklists

Standardizing safety gear for specific jobs simplifies compliance. Workers are more likely to wear the correct equipment when they have clear, task-specific instructions.

Use these simple lists to verify your team has the right protection for the job at hand.

- Routine Inspection: Non-slip boots, safety glasses, hard hat, high-vis vest.

- Mechanical Maintenance: Hard hat, safety glasses, cut-resistant gloves, steel-toe boots, and hearing protection.

- Chemical Handling: Chemical gloves, face shield over goggles, chemical-resistant apron, respirator (if required by SDS).

- Confined Space Entry: Full-body safety harness, tripod/winch system, atmospheric monitor, respirator.

- High-Elevation Tasks: Full-body harness, double lanyard, hard hat with chin strap, tool lanyards.

Conclusion

Safety in cooling tower operations is non-negotiable. With risks like chemical exposure, biological hazards such as Legionella, falls, and confined space dangers, a robust PPE strategy is crucial. This cooling tower PPE guide emphasizes the importance of adhering to OSHA standards for selecting the right gear.

Essential PPE includes hard hats, safety goggles, non-slip boots, and gloves. However, specific tasks demand advanced protection like chemical-resistant suits, respiratory masks, and fall arrest systems. Implementing a successful safety program involves thorough risk assessments, regular training, and consistent enforcement by supervisors.

By prioritizing proactive hazard protection and using the right cooling tower PPE, companies can keep workers safe and maintain operational reliability. If you need cooling tower experts for any service, contact ICST today and let our safety professionals support your needs.

Frequently Asked Questions

What PPE is essential for cooling tower maintenance?

Essential PPE typically includes a hard hat, safety glasses or goggles, non-slip boots, and work gloves. Specific tasks like chemical handling or working at heights require additional gear such as face shields, chemical suits, and safety harnesses.

What standards govern cooling tower PPE selection?

OSHA standards (29 CFR 1910) primarily govern PPE selection. Specifically, 1910.132 covers general requirements, 1910.133 covers eye/face protection, and 1910.134 covers respiratory protection.

How do you maintain and inspect cooling tower PPE?

Inspect PPE daily for cracks, tears, or wear. Replace damaged gloves, check harness integrity, clean respirator filters, and verify that helmets and eye protection meet safety standards. Record inspections for compliance.