For plant engineers in Thailand, the monsoon season brings more than just heavy rain; it unleashes the “Monsoon Surge.” This sudden flood of fresh, acidic water might seem harmless, but it can wreak havoc on your cooling tower’s delicate water chemistry. This imbalance triggers a triple threat: it washes away protective chemicals, introduces organic matter that breeds dangerous bacteria like Legionella, and overwhelms your system, risking costly damage and downtime.

The dilution effect washes away essential chemical inhibitors, leaving core components vulnerable to corrosion and scaling. At the same time, rainwater introduces organic materials that act as nutrients for dangerous biofouling, increasing the risk of Legionella. Finally, the sheer volume of water can overwhelm the system, leading to overflows, equipment damage, and costly downtime.

In this blog, we will discuss why a proactive strategy, incorporating preparation and automation, is essential for managing these risks. By understanding how to master your cooling tower water chemistry, you can protect your assets and turn the monsoon from a threat into a manageable event.

Table of Contents

ToggleThe Immediate Threat: CoC Crash and Corrosion

Rainwater dramatically lowers the conductivity and Total Dissolved Solids (TDS) of the cooling water. This sudden change collapses the Cycles of Concentration (CoC) and effectively strips the water of the protective inhibitors that shield your system from damage. Without these safeguards, metal components are left exposed and vulnerable.

Understanding Cycles of Concentration (CoC)

How does rainwater dilution impact your system’s protection? The answer lies in the Cycles of Concentration. CoC is a ratio that compares the level of dissolved solids in the cooling tower water to the level in the makeup water. A higher CoC means water is being used more efficiently.

Critically, the concentration of your chemical inhibitors, which prevent scale and corrosion, is directly tied to the CoC. When a monsoon surge dumps low TDS rainwater into the system, the CoC plummets, and your expensive chemical protection is washed away with it.

The Corrosivity Spike

When the CoC crashes, the dilution of corrosion inhibitors leaves metal components dangerously exposed. Galvanized steel and other vulnerable metals face an immediate and accelerated risk of corrosion. This is not a slow degradation; it is a rapid, corrosive attack that can cause significant damage in a short period.

Actionable Step:

- Track the threat in real-time: Implement monitoring of corrosion coupons or install online corrosion monitors.

- Focus on peak rainy periods: Monitor metal loss rates closely during these times.

- Gain direct insight: Use the data gathered to check the effectiveness of your chemical program.

The pH Factor

Rainwater is often naturally acidic, with a lower pH than your system’s makeup water. A sudden drop in the system’s pH accelerates general corrosion across all metal surfaces. It is crucial to monitor and control the pH to prevent it from dipping into a corrosive range, which would compound the damage from inhibitor dilution.

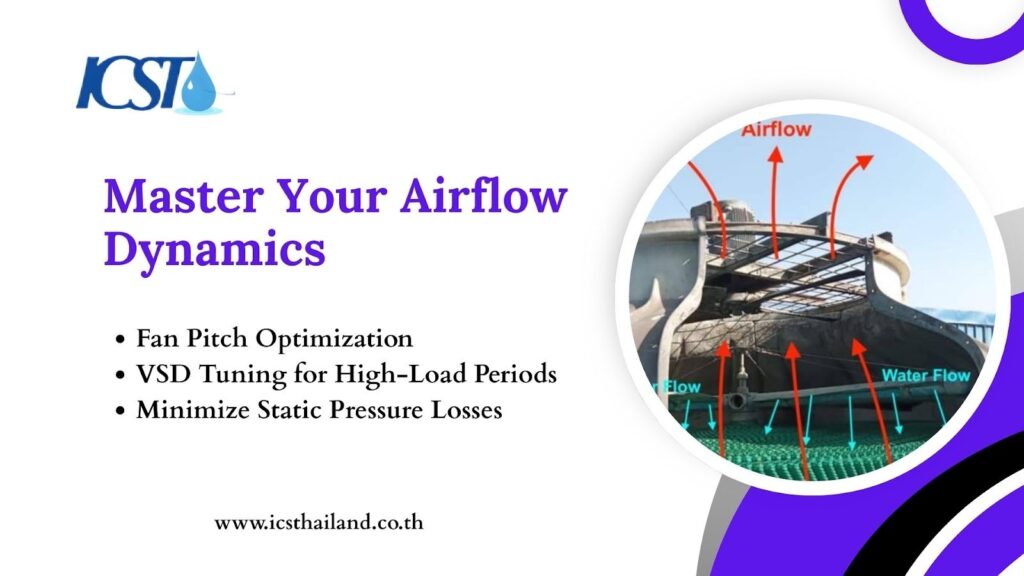

Checkpoint Strategy 1: Automation for Dynamic Conditions

During a monsoon surge, water chemistry changes too rapidly for manual sampling and adjustment. A manual approach cannot keep pace with the dynamic conditions. Automation is not a luxury; it is a non-negotiable requirement for a rapid and effective response.

The Conductivity (TDS) Controller

The conductivity controller is the heart of your monsoon stabilization strategy. This device continuously monitors the water’s TDS level and automatically manages the blowdown valve to maintain a target setpoint. How can you prepare it for the rain?

Proactive Adjustment:

- Pre-set the blowdown setpoint higher than the normal operating level before the monsoon season.

- This adjustment minimizes rainwater dilution in the system.

- It tightens the operating range to prevent excessive blowdown.

- Helps preserve the cooling tower’s water chemistry during heavy rains.

Proportional Chemical Dosing

Simple on/off chemical dosing is insufficient during a monsoon. Your system must be configured for proportional feed to replenish inhibitors as they are diluted. Why is this distinction so important?

- Corrosion Inhibitors: Dosing must be linked directly to the makeup water flow or total system volume, not just to blowdown cycles. This ensures that protective inhibitors are replenished immediately after a rain dilution event, rather than waiting for the next blowdown cycle, which may be hours away.

- Scale Inhibitors: The same proportional principle applies to scale inhibitors. Maintaining the required concentration is essential to keep hardness minerals like calcium and magnesium suspended in the water, preventing them from precipitating as damaging scale on heat exchange surfaces.

Checkpoint Strategy 2: Targeting Biofouling and Legionella Risk

The combination of warm temperatures, diluted water, and an influx of organic nutrients from rainwater creates an ideal breeding ground for bacteria, algae, and biofilm. These conditions sharply increase the risk of microbial-induced corrosion and, most critically, the proliferation of Legionella pneumophila.

Biocide Program Shift

A standard maintenance biocide program is not enough to handle a monsoon-driven biological bloom. To address this challenge effectively, it’s essential to implement a more aggressive program designed to combat the intensified biological activity caused by the monsoon.

- Oxidizing Biocides (Chlorine/Bromine): Increase the frequency of shock treatments. Chlorine and bromine are powerful oxidizers that quickly kill free-floating microorganisms introduced by rainwater.

- Non-Oxidizing Biocides: Implement slug dosing of non-oxidizing biocides like glutaraldehyde or isothiazolin. Glutaraldehyde and isothiazolin are highly effective at penetrating and removing existing biofilm buildup from the cooling tower fill, basin, and critical heat exchangers.

System Disinfection

The most effective way to control biological growth during the monsoon is to start with a clean slate. We strongly recommend scheduling a full system disinfection, or biocide clean, before the rainy season begins. This proactive measure eliminates pre-existing biofilm, which would otherwise serve as a seed for rapid and uncontrollable growth when nutrient levels spike. Here’s why it’s important:

- Schedule a full system disinfection or biocide clean before the monsoon begins.

- This process removes pre-existing biofilm, preventing it from acting as a base for growth.

- Proactive cleaning ensures your system is protected when nutrient levels spike during the rainy season.

Filtration

Rain introduces suspended solids, dust, and organic debris into your cooling tower, which can clog system components and feed biofouling. To prevent this, side-stream filtration plays a crucial role. A properly sized filter continuously removes contaminants, keeping the water clean and starving microorganisms of nutrients.

To implement side-stream filtration effectively, follow these steps:

- Analyze Your System Needs: Evaluate the size of your new cooling tower and the water quality to determine the appropriate filter size and type.

- Choose the Right Filter: Common options include sand filters, cartridge filters, or centrifugal separators. Select the one best suited to remove the debris your system collects.

- Install on the Side Stream: Position the filter on a portion of the water flow (typically 5-10% of the total flow) to continuously clean the water without disrupting the main system.

- Set a Maintenance Schedule: Regularly inspect and clean the filter to prevent clogs and ensure optimal performance.

- Monitor Water Quality: Use water testing to ensure contaminants are effectively removed and make adjustments if needed.

By consistently maintaining and monitoring your filtration system, you can extend your new cooling tower’s lifespan and improve its efficiency.

Checkpoint Strategy 3: Mechanical and Physical Preparation

A monsoon surge is also a physical threat. The sheer volume of water can overwhelm the system, leading to overflows that waste treated water and chemicals, and potentially cause significant physical damage to the tower and surrounding equipment.

Overflow Management

Are your drains ready for a deluge? Inspect and confirm that all overflow lines and primary basin drains are clear of obstructions and correctly sized to handle the highest expected rainfall rate for your location. A clogged drain can turn a manageable rain event into a catastrophic overflow.

Debris Barriers

Want to keep your cooling system clean and efficient? Your best bet is to prevent debris from getting in from the start. Keeping your system’s barriers in top shape is crucial for avoiding clogs and bacterial growth. Here’s what to check:

- Inspect Barriers: Ensure that all intake strainers, basin screens, and drift eliminators are clean, secure, and in good repair.

- Prevent Clogs: These barriers are your first line of defense against large organic debris like leaves and sediment.

- Avoid Contamination: Debris can clog spray nozzles, foul heat exchangers, and create stagnant zones perfect for bacterial growth.

Water Tightness

Maintaining a watertight cooling tower is essential to prevent contamination. Any cracks or breaches in the tower’s casing, joints, or basin can allow untreated ground runoff to enter the system. This bypasses the makeup water system, introducing contaminants that disrupt your water chemistry.

- Check for Leaks: Inspect the cooling tower casing, joints, and basin for any cracks or breaches.

- Prevent Runoff Contamination: External ground runoff can introduce untreated, contaminated water directly into your basin.

- Maintain Water Chemistry: Sealing these entry points is a vital step in maintaining control over your cooling tower’s water chemistry.

Conclusion

Monsoon stability is not a matter of luck; it is the result of a deliberate, multi-faceted strategy. This stability is achieved through three essential pillars: Automated Control to respond instantly to changing conditions, an Aggressive Biocide Strategy to prevent dangerous biological growth, and robust Physical Preparedness to handle the mechanical stress of heavy rainfall.

By proactively addressing the risks of a CoC crash and nutrient loading, facilities in Thailand can protect their cooling systems. This foresight helps avoid the costly consequences of unexpected shutdowns, emergency repairs, and lost production. A stable system is a profitable system.

Do not wait for the rain to reveal the weaknesses in your system. Contact ICS Thailand today for an on-site Water Chemistry Audit and automated controller calibration. Let us help you weatherproof your cooling system against the Thailand monsoon surge and ensure your operations remain stable and profitable.

Frequently Asked Questions

Why does CoC crash during heavy rainfall?

Rainwater has very low dissolved solids. When large volumes enter the tower, they instantly reduce TDS, causing the CoC ratio to drop. This directly reduces the concentration of protective corrosion and scale inhibitors.

What happens to corrosion levels when CoC drops?

A CoC drop exposes metal surfaces because corrosion inhibitors become too diluted to protect the system. This causes a rapid spike in corrosion, especially on galvanized steel and uncoated metal parts.

How does rainwater impact pH in cooling towers?

Rainwater is naturally acidic, so it lowers system pH during monsoon events. Low pH accelerates corrosion and destabilizes chemical balance, making pH monitoring essential.

How does monsoon rain affect cooling tower water chemistry?

Monsoon rain dilutes the cooling water, lowering TDS and collapsing the Cycles of Concentration (CoC). This washes out chemical inhibitors, increases corrosion risk, and introduces organic matter that fuels bacterial growth.