Imagine standing in a bustling city at night, the glow of lights illuminating the skyline. Behind the scenes, deep within power plants, unsung heroes are working diligently on heat exchangers. These ingenious devices quietly ensure energy flows efficiently, transferring heat between fluids without ever letting them mix.

The same technology is at play in food processing plants, helping bring your favorite meals to life. Whether it’s powering your home or preparing your dinner, heat exchangers are the invisible force driving countless industrial processes we rely on every day.

This comprehensive guide explores the main types of heat exchangers, examines their specific industrial applications, and provides crucial insights into maintenance practices that ensure peak performance.

The industrial landscape heavily depends on effective heat transfer. Whether you manage a chemical processing plant, oversee HVAC systems, or work in power generation, the principles and applications of heat exchangers covered here will enhance your understanding of these critical components.

Table of Contents

ToggleThe Fundamental Principle: How Heat Exchangers Work

Heat exchangers operate on a simple thermodynamic principle: heat naturally flows from a hotter fluid to a cooler one. This process occurs through conduction, convection, or radiation, depending on the specific design and application.

- Counter-flow represents the most efficient configuration. Hot and cold fluids move in opposite directions, maximizing the temperature difference between them throughout the heat exchanger length. This arrangement achieves the highest possible heat transfer rates.

- Parallel-flow configurations have both fluids moving in the same direction. While simpler to implement, this design limits heat transfer efficiency because the temperature difference decreases along the flow path.

- Cross-flow arrangements position fluids perpendicular to each other. This configuration offers a balance between efficiency and practical design considerations, making it popular in air conditioning and automotive applications.

The Main Types of Heat Exchangers and Their Applications

Modern industrial processes rely on several distinct heat exchanger types. Each design offers specific advantages that make it suitable for particular applications and operating conditions.

Type 1: Shell and Tube Heat Exchangers

Shell and tube heat exchangers feature a bundle of tubes housed within a large cylindrical shell. One fluid flows inside the tubes while another circulates outside them within the shell space.

These units handle extreme operating conditions with remarkable durability. They withstand high pressures and temperatures that would damage other heat exchanger types. The robust construction allows for easy tube replacement and internal inspection.

Industrial Applications:

- Chemical Processing & Oil & Gas: Refineries use shell and tube exchangers for cooling reactor effluents and condensing hydrocarbon vapors. Their ability to handle corrosive chemicals and high pressures makes them indispensable in these demanding environments.

- Power Generation: Steam power plants employ these exchangers as condensers, converting exhaust steam back to water. The large surface area accommodates massive steam flows while maintaining structural integrity under vacuum conditions.

- Marine & Shipbuilding: Ships require reliable cooling systems for engines and auxiliary equipment. Shell and tube exchangers provide dependable service in the harsh marine environment where maintenance access is limited.

Type 2: Plate Heat Exchangers (PHE)

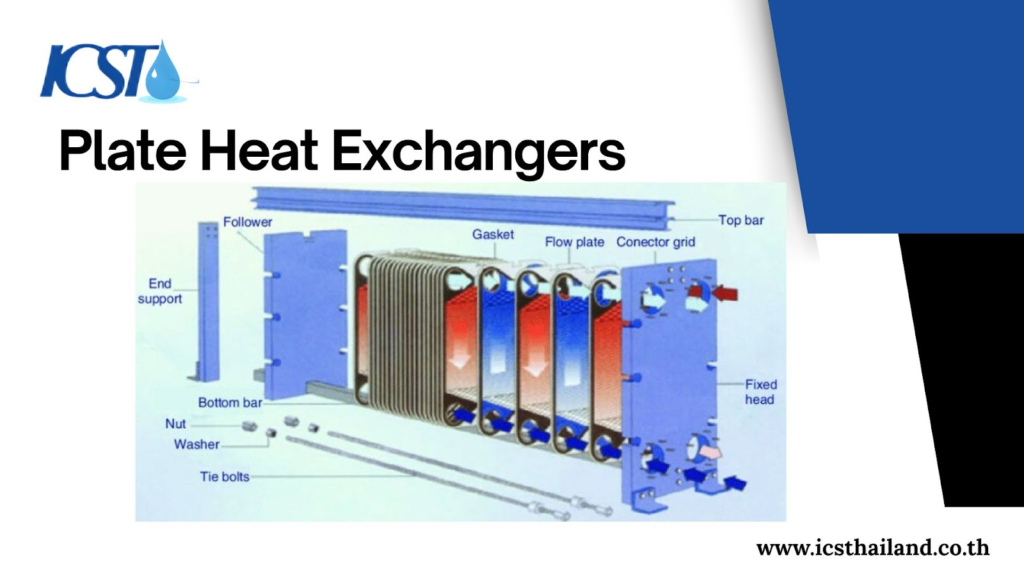

Plate heat exchangers consist of thin, corrugated metal plates stacked together with gaskets. Fluids flow through alternating channels between plates, creating multiple heat transfer surfaces in a compact design.

Industrial Applications:

- Food & Beverage: Dairy processing relies heavily on plate heat exchangers for pasteurization and sterilization. Milk, juice, and other liquid foods require precise temperature control while maintaining sanitary conditions. The ability to disassemble plates for thorough cleaning makes PHEs ideal for these applications.

- HVAC & Refrigeration: Large commercial chillers use plate heat exchangers as evaporators and condensers. The compact design allows building engineers to maximize cooling capacity while minimizing equipment room space requirements.

- Pharmaceuticals: Drug manufacturing processes demand exceptional cleanliness and temperature precision. Plate heat exchangers provide the necessary control while allowing complete disassembly for validation and cleaning between batches.

Type 3: Air-Cooled Heat Exchangers (Finned Tube)

Air-cooled heat exchangers feature tubes with external fins that dramatically increase surface area. Fans force ambient air across the fins to remove heat from the fluid flowing inside the tubes.

- Petrochemical Refining: Remote processing facilities often lack adequate water supplies for conventional cooling. Air-cooled exchangers provide reliable heat removal for product cooling and vapor condensation in these challenging locations.

- Power Plants: Dry-cooling systems use air-cooled exchangers to condense steam without consuming water resources. This approach becomes increasingly important in arid regions where water conservation is critical.

- Gas Pipelines: Natural gas compression stations require cooling between compression stages. Air-cooled exchangers handle this duty reliably while minimizing environmental impact and operating costs.

Comparison of Common Industrial Heat Exchangers

Understanding the trade-offs between different heat exchanger types helps engineers make informed selections. Consider these key factors when evaluating options for your application:

| Feature | Shell and Tube | Plate Heat Exchanger (PHE) | Air-Cooled (Finned Tube) |

| Upfront Cost | Moderate to High | Moderate | High |

| Energy Efficiency | Moderate | High | Moderate |

| Space Requirements | Large footprint; requires significant floor space | Compact; requires minimal floor space | Large footprint; no water needed |

| Maintenance & Cleaning | Difficult; requires tube removal and specialized cleaning | Easy; plates can be disassembled and cleaned | Moderate; requires fan and fin cleaning |

| Best For | High-pressure, high-temperature applications; large-scale processes | Food & beverage, HVAC, and pharmaceuticals; applications needing high efficiency in a compact space | Water-scarce locations; petrochemical and power plants |

| Primary Advantage | Highly robust and versatile for harsh conditions | Extremely efficient and compact | Eliminates water usage and associated costs |

Critical Maintenance: Common Challenges and Solutions

Effective maintenance practices determine heat exchanger performance and service life. Two primary challenges threaten optimal operation and require proactive management strategies.

Problem 1: Fouling and Scaling

Fouling occurs when unwanted deposits accumulate on heat transfer surfaces. These deposits include mineral scale, biological growth, corrosion products, and process contaminants.

The impact on system performance is immediate and measurable. Fouling reduces heat transfer efficiency by creating thermal resistance between fluids. Pressure drops increase as deposits restrict flow passages, forcing pumps and fans to work harder.

What solutions address fouling effectively?

- Chemical cleaning removes deposits through acid washing, alkaline cleaning, or specialized solvents matched to specific fouling types

- Mechanical cleaning employs high-pressure water jets, brushes, or specialized tools to physically remove stubborn deposits

- Filtration systems prevent contaminants from entering the heat exchanger, reducing fouling rates significantly

Problem 2: Corrosion and Leaks

Corrosion attacks heat exchanger materials through chemical reactions with process fluids or environmental conditions. This degradation weakens structures and creates leak paths that compromise system integrity.

How do you prevent corrosion effectively?

- Proper material selection matches heat exchanger construction materials to process conditions, using stainless steel, titanium, or specialized alloys as needed

- Regular inspections identify corrosion before it causes failures, allowing planned maintenance instead of emergency repairs

- Effective water treatment controls pH, removes oxygen, and adds inhibitors to minimize corrosive conditions

How to Select the Right Heat Exchanger for Your Needs

Selecting the optimal heat exchanger requires a systematic evaluation of application requirements and operating constraints. Ask these critical questions during the selection process:

- What are the fluid characteristics? Consider viscosity, corrosiveness, fouling tendency, and phase changes. These properties directly influence material selection and design configuration.

- What are the operating conditions? Temperature ranges, pressure levels, and flow rates determine structural requirements and heat transfer surface area needs.

- What are the space and location constraints? Available floor space, height restrictions, and access requirements influence equipment configuration and maintenance procedures.

- How critical is energy efficiency? High-efficiency units cost more initially but provide ongoing energy savings. Calculate lifecycle costs to determine the optimal balance.

- What are the maintenance requirements and budget? Consider cleaning frequency, access requirements, and skilled labor availability when evaluating different designs.

Conclusion

Heat exchangers represent critical components in industrial thermal management systems. Proper selection, installation, and maintenance practices ensure optimal performance while minimizing operating costs and downtime risks.

The key to success lies in understanding how different heat exchanger types match specific application requirements. Shell and tube units excel in high-pressure, high-temperature services. Plate heat exchangers provide maximum efficiency in compact installations. Air-cooled systems eliminate water dependency while maintaining reliable performance.

Proactive maintenance programs protect your heat exchangers’ investment and ensure consistent performance. Address fouling and corrosion before they impact operations. Implement monitoring systems that detect performance degradation early, allowing planned maintenance instead of emergency repairs.

Do not let inefficient thermal management compromise your operations. Contact ICS Thailand today for expert advice and a tailored solution that meets your specific industrial needs.

Frequently Asked Questions

What is a heat exchanger?

A heat exchanger is an ingenious device that transfers heat between two or more fluids without them ever mixing, ensuring energy flows efficiently in various industrial processes.

What are the main types of heat exchangers?

The three main types of heat exchangers are shell and tube, plate heat exchangers (PHE), and air-cooled (finned tube) exchangers.

What is the most efficient heat exchanger flow configuration?

The counter-flow configuration is the most efficient because the hot and cold fluids move in opposite directions, maximizing the temperature difference and achieving the highest possible heat transfer rates.

What is fouling, and why is it a problem?

Fouling is the accumulation of unwanted deposits like mineral scale and rust on heat transfer surfaces. It is a problem because it reduces heat transfer efficiency, increases pressure drops, and forces systems to use more energy.

What is the primary advantage of an air-cooled heat exchanger?

The primary advantage is that it eliminates the need for a water source for cooling. This makes it a perfect solution for industrial applications in water-scarce or remote locations.