From your morning coffee cup to the books you read and the packages you receive, paper is everywhere. In fact, an average person uses between 25,000 and 100,000 sheets of paper each year! But this essential material comes with a hefty environmental cost. The paper industry is a massive consumer of water, making its environmental impact a major concern.

What’s fascinating, though, is how this industry is tackling its challenges head-on. Despite its high water usage, it’s among the most proactive in adopting sustainable practices, particularly through “closed-loop” systems. These systems aim to recycle water within operations, reducing freshwater demands and minimizing waste.

By striving for more efficient cooling and water reuse, the paper industry is setting an example of how necessity can drive innovation in sustainability.

In this blog post, we will explore the essential treatment train and cooling management strategies that convert paper mill process water into reliable cooling tower makeup. This approach is key for effective Paper Mill Cooling, driving down operating costs and securing compliance.

Table of Contents

ToggleWhy Paper Mill Water is Uniquely Difficult for Cooling

Paper mill process water is notoriously challenging to reuse in cooling systems due to its specific blend of contaminants. The high concentration of suspended solids, organic compounds, and inorganic ions creates a hostile environment for cooling equipment.

Without proper pre-treatment, these contaminants lead to significant operational issues, reducing efficiency and increasing maintenance costs. Understanding the nature of these contaminants is the first step toward designing an effective recycling solution.

Unique Contaminants

What makes this water so difficult to handle? The primary culprits are specific to the papermaking process.

Suspended Solids (TSS)

Fine cellulose fibers and fillers easily pass primary screens, causing rapid fouling in heat exchangers, pump seal areas, and cooling tower parts such as distribution nozzles.

High Organic Load (COD/BOD)

Lignin and dissolved wood materials act as a massive nutrient source, fueling aggressive microbial growth and the formation of tenacious biofilms (biofouling).

Inorganic Load

High concentrations of dissolved ions, particularly calcium, silicates, and sulfate, become highly aggressive scale-formers as water evaporates and concentrates in the cooling tower.

Impact on Cooling Systems

How do these contaminants directly harm your cooling infrastructure? Their effects are both immediate and cumulative.

Heat Transfer Loss

Fouling from suspended solids and biological biofilms creates an insulating layer on heat exchanger surfaces, drastically reducing the efficiency of condensers and process coolers.

Corrosion Risk

The buildup of dissolved solids and corrosive byproducts from anaerobic decay aggressively attacks metal surfaces. This damage shortens equipment life and increases the need for cooling tower repair.

Operational Instability

Rapid and unpredictable changes in water quality can disrupt chemical treatment programs, leading to process upsets, inefficient chemical use, and potential system failure.

Foaming Tendencies (Operational Hazard)

Residual surfactants, defoamers, and sizing agents from the paper machine process can carry over into the cooling loop, causing severe and persistent foaming in the tower basin. This results in water loss, chemical inefficiency, and potential pump cavitation.

The Solution: Essential Water Recycling & Pre-Treatment Train

To successfully reuse paper mill process water for cooling, a multi-stage treatment train is not just recommended; it is essential. This systematic approach removes contaminants in a specific order, transforming a problematic wastewater stream into a valuable asset.

Each stage targets a different type of impurity, ensuring the final water quality is suitable for the demanding environment of a cooling tower. This process is the foundation of a reliable and cost-effective water recycling program.

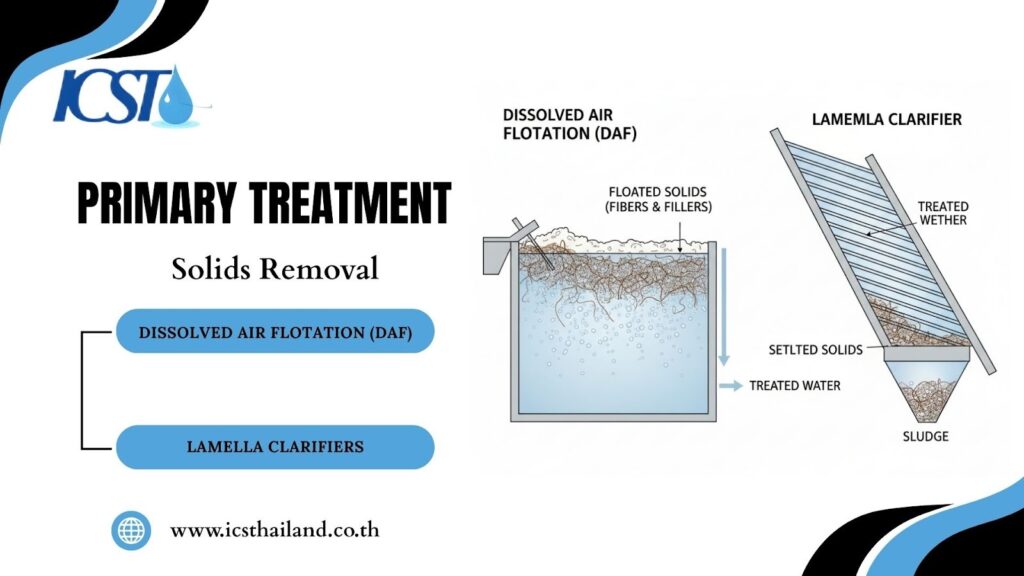

Primary Treatment: Solids Removal

The first and most critical step is to remove the bulk of suspended solids. How do you efficiently handle the high load of fibers and fillers? These solids can quickly clog equipment and reduce system efficiency if not addressed early. Effective removal at this stage prevents a cascade of problems later in the treatment process.

- Technology: The most effective technologies for this stage are Dissolved Air Flotation (DAF) and Lamella Clarifiers.

- Goal: These systems are designed for the efficient bulk removal of fibers, fillers, and other total suspended solids (TSS), preventing immediate physical fouling downstream.

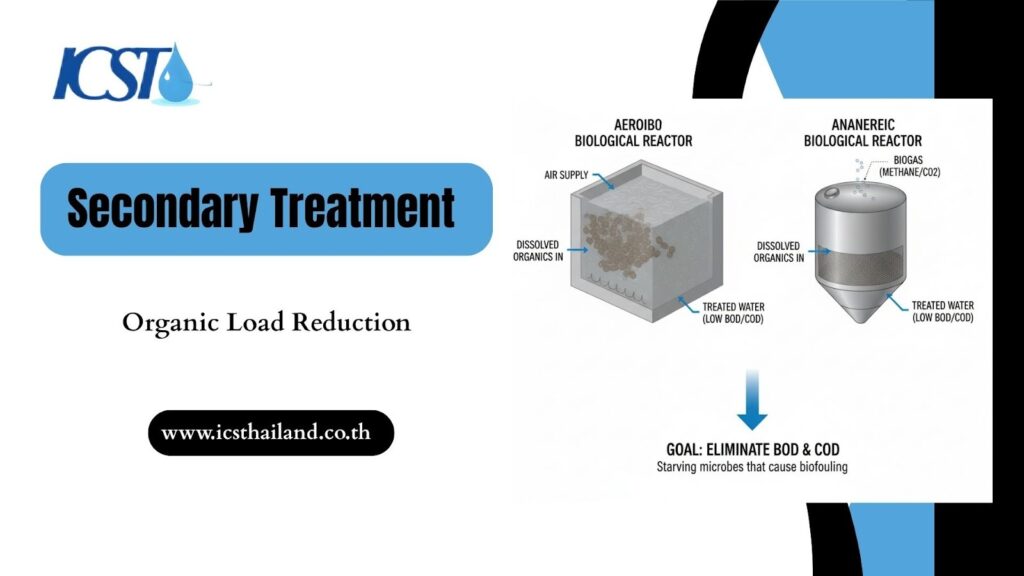

Secondary Treatment: Organic Load Reduction

With the solids removed, the next challenge is the high concentration of dissolved organics. How do you eliminate the food source for damaging biofilms?

Advanced filtration methods can help, but they often come with high costs and maintenance. Finding an efficient, cost-effective solution is key to preventing biofilm formation.

The Power of Biological Reactors

Biological reactors, whether aerobic or anaerobic, are the true champions of organic reduction. These advanced systems work tirelessly to break down organic matter, paving the way for cleaner and more efficient processes.

Eliminating the Culprits: BOD and COD

This stage is all about drastically reducing Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD). By starving the microbes responsible for biofouling in cooling towers, this step becomes the game-changer in any successful recycling program.

Tertiary Treatment: The Polish for Cooling Reuse

After primary and secondary treatment, the water is much cleaner but may still contain fine particles and dissolved salts that can cause issues in cooling systems. So, what is the final polishing step to ensure the water is ready for reuse?

This tertiary treatment stage acts as a final purification barrier, targeting the remaining impurities to produce high-quality water suitable for cooling towers.

- Microfiltration/Ultrafiltration (UF): These membrane filtration systems remove any remaining fine colloidal matter and bacteria, preparing the water for its final use or further purification.

- Reverse Osmosis (RO): While optional for some, RO is a key technology for mills targeting Near-Zero Liquid Discharge (NZLD). Removing dissolved salts produces exceptionally clean water and allows for higher cycles of concentration in new cooling towers.

Optimized Cooling Tower Management for Recycled Water

Treating the water before it enters the cooling loop is only half the battle. Once this recycled water is in the paper mill cooling system, it requires a specialized management strategy to handle the remaining, now concentrated, impurities.

An optimized approach combines advanced chemical treatments with mechanical upgrades to ensure long-term reliability and peak performance. This proactive management prevents the gradual degradation of cooling efficiency and protects valuable equipment from damage.

Chemical Treatment Programs (The Critical Difference)

Managing this unique water chemistry requires a sophisticated, multi-faceted program. This isn’t a one-size-fits-all situation; the concentrated impurities demand a targeted chemical strategy.

An effective program moves beyond basic treatments to address the specific challenges posed by recycled water, ensuring the system remains clean and efficient.

- Advanced Scale Control: This involves using high-performance polymer dispersants and crystal modifiers specifically designed to manage the concentrated residual salts and prevent scale formation.

- Aggressive Bio-Control: An effective strategy includes a rotating program of oxidizing and non-oxidizing biocides. This prevents microbes from developing resistance and controls the growth fueled by any residual organics.

- Automated Dosing: Relying on real-time conductivity and pH monitoring allows for precise chemical dosing. This optimizes Cycles of Concentration (COC), minimizes chemical waste, and maintains stable water quality.

Mechanical and Filtration Upgrades

Physical upgrades are essential for protecting your cooling system from breakthrough contaminants. These mechanical and filtration improvements are designed to handle unexpected solids and prevent them from disrupting operations.

Implementing the right physical safeguards ensures the long-term reliability and efficiency of the system.

- Side-Stream Filtration: Continuously filtering a portion of the cooling water using media filters or automatic screen filters is crucial. This catches any breakthrough suspended solids and prevents them from fouling heat exchangers.

- Anti-Fouling Components: It is wise to install wide-flow, anti-clogging nozzles and high-fouling-resistant fill media within the cooling tower. These components are designed to handle water with higher solids content without compromising performance.

When systems reach the end of their lifecycle, experts often recommend cooling tower maintenance or complete replacement to build new cooling tower units equipped with modern, high-efficiency designs that reduce water and energy consumption.

Final Thoughts

Paper mill water recycling, though a complex undertaking, is an essential strategic investment. It represents a vital shift from a linear “use-and-dispose” model to a circular, closed-loop economy.

This transition creates significant benefits for paper mills by reducing water, wastewater, chemicals, and energy consumption, resulting in major operational savings. It also strengthens environmental compliance by meeting ZLD targets and boosts system reliability by protecting critical assets, minimizing downtime, and increasing production.

Ultimately, embracing water recycling creates a more efficient, resilient, and profitable operation, which is essential for modern paper mill cooling processes.

Ready to transform your water management strategy? Contact ICST for a custom water audit and system design consultation to implement your advanced cooling water recycling solution.

Frequently Asked Questions

How do closed-loop cooling systems work in paper mills?

Closed-loop systems continuously circulate and treat water, allowing reuse without major losses, which improves efficiency and reduces wastage.

How does recycled water affect cooling tower performance?

Recycled water can improve performance when properly treated, but may cause scaling, corrosion, or biofouling if contaminants remain untreated.

What role do biological reactors play in Paper Mill?

Biological reactors break down organic matter, reducing BOD and COD levels, and preventing microbial growth in cooling towers.

How does a pH change cause corrosion in the cooling system?

Process shifts can cause sudden pH and alkalinity changes, leading to unpredictable corrosion rates on metal components, especially when combined with corrosive byproducts from organic decay.

Can recycled water meet Zero Liquid Discharge targets?

Yes. With reverse osmosis and advanced filtration, recycled water can achieve near-ZLD compliance, minimizing environmental impact.