In tropical climates, facility managers and engineers face a constant battle against heat and humidity. Your cooling tower is the heart of your HVAC system, but in these environments, it operates against a formidable, invisible barrier: the wet-bulb temperature. This single metric dictates the maximum possible cooling your system can achieve.

So, how can you break through this thermal ceiling and unlock significant energy savings?

This guide moves beyond standard maintenance checklists. We will explore the critical metric of “approach” and provide a comprehensive framework for maximizing your wet-bulb drop.

To truly optimize a tropical climate cooling tower, you must shift from passive upkeep to aggressive, integrated strategies across four key areas: airflow dynamics, bio-control, chemical management, and system design.

Implementing these strategies will not only enhance cooling performance but also deliver substantial reductions in chiller energy consumption.

Table of Contents

ToggleThe Wet-Bulb Barrier and the Metric That Matters

Before diving into optimization strategies, it’s crucial to understand the fundamental physics at play. The Wet-Bulb Temperature (WBT) is the lowest temperature to which water can be cooled by evaporation under current atmospheric conditions.

In hot, humid tropical regions, the WBT is inherently high, which means the potential temperature difference (delta T) between the incoming hot water and the outgoing cold water is naturally small.

This is where the “approach” becomes the most important performance indicator. The approach is the difference between the Leaving Water Temperature (LWT) and the Wet-Bulb Temperature (LWT – WBT).

- A standard cooling tower typically achieves an approach of 8°F (4.4°C).

- Optimized systems can reduce this to 5°F (2.8°C) or even lower.

- A 3°F improvement may seem minor, but it leads to significant energy savings at the chiller.

- The chiller is usually the largest energy consumer in cooling systems.

- Maximizing wet-bulb drop depends on achieving the tightest approach possible.

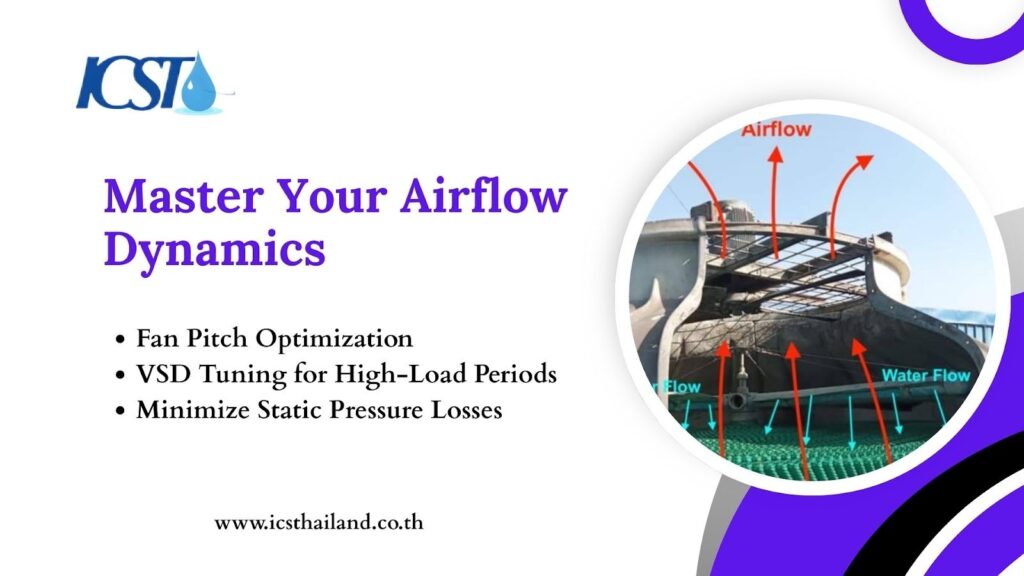

Strategy 1: Master Your Airflow Dynamics

Since the wet-bulb temperature is a fixed atmospheric condition, the most direct way to improve thermal rejection in a tropical climate cooling tower is to maximize the contact between air and water. This means optimizing every aspect of your cooling tower’s airflow.

Fan Pitch Optimization

The single most influential factor in airflow is the fan. Ensure your fan blades are pitched to move the maximum possible volume of air, measured in Cubic Feet per Minute (CFM), without exceeding the motor’s full load amperage (FLA).

This isn’t a “set and forget” adjustment. In tropical regions with distinct wet and dry seasons, seasonal fan pitch adjustments are often necessary to maintain peak performance year-round.

VSD Tuning for High-Load Periods

Variable Speed Drives (VSDs) are typically seen as energy-saving devices, but they are also powerful performance tools. During the hottest parts of the day when WBT and cooling loads are at their peak, program your VSDs either manually or automatically to run fans at 100 percent capacity.

While this temporarily increases fan energy consumption, the resulting improvement in chiller efficiency provides a far greater net energy saving for the entire system.

Minimize Static Pressure Losses

Anything that obstructs airflow robs your system of efficiency. This obstruction forces the fans to work harder to pull the same amount of air through the tower, leading to increased energy consumption.

- Louvers: Clogged or scaled louvers restrict air intake. Keep them clean and free of any debris to ensure maximum airflow into the tower.

- Drift Eliminators: While necessary to prevent water loss, old or inefficient drift eliminators can create significant static pressure. Upgrade to modern, high-efficiency, low-pressure-drop eliminators that meet regulatory standards while minimizing their impact on airflow.

Strategy 2: Defeat the Biofilm Barrier

In the warm, nutrient-rich water of a tropical cooling system, biofilm is a relentless enemy. This slimy layer of microorganisms acts as a powerful insulator, severely hampering heat transfer.

The Insulating Effect of Biofilm

It’s hard to overstate the impact of biofouling. A layer of biofilm just 0.001 inches thick on cooling tower fill media or heat exchanger tubes can reduce thermal transfer efficiency by a staggering 15-20%. This insulation prevents the water from giving up its heat to the air, directly widening your approach and costing you money.

Aggressive Biocide Rotation

A robust chemical treatment plan is essential to prevent biofilm buildup. The key is to prevent microbes from developing resistance to your biocides. Here’s how to do it:

- Rotate Biocides: In consistently warm water, microbes can become resistant to a single biocide. To prevent this, rotate different chemical treatments on a strict schedule.

- Use a “One-Two Punch”: Alternate between an oxidizing biocide (like stabilized bromine) and a non-oxidizing biocide (like DBNPA).

- Prevent Adaptation: This alternating approach stops microbial populations from adapting and thriving in your system.

Mandate Side-Stream Filtration

Side-stream filtration is essential for high-performance cooling towers in tropical climates. It continuously filters a portion of the system’s water, removing the solids and organic matter that microbes feed on. This reduces the biological demand and makes your chemical treatments much more effective.

- Continuous Filtration: By constantly filtering a portion of the system water, you remove suspended solids (TSS) and organic matter.

- Starve Microbes: This process removes the food source for microbes.

- Boost Chemical Effectiveness: With less biological demand, your chemical treatment program becomes significantly more efficient.

Strategy 3: Chemical Control for Monsoon and Scale

Tropical climates can be unpredictable, with sudden heavy monsoons that can drastically alter water chemistry in an instant. For a tropical climate cooling tower, it’s crucial to have a chemical control program that’s not only reliable but also automated to adapt seamlessly to these rapid changes.

Monsoon-Proof Your TDS Control

Heavy rainfall can rapidly dilute the water in your cooling tower, causing Total Dissolved Solids (TDS) levels to plummet. Your conductivity controller must be programmed to recognize and manage these dilution events.

It needs to adjust the blowdown (or bleed) rate quickly to bring the Cycles of Concentration (CoC) back to the target range, maintaining system protection.

Ensure Phosphate and Inhibitor Stability

High water temperatures accelerate the rate of chemical reactions, increasing the risk of mineral scale, particularly calcium phosphate. Your chemical inhibitor program must be specifically formulated for high-temperature stability to prevent scale from forming on critical heat transfer surfaces.

Automate pH Monitoring and Adjustment

Rapid organic growth, rainfall, and airborne contaminants can all cause wild swings in water pH. These fluctuations can lead to several issues, including corrosion, reduced biocide effectiveness, and increased scale potential. Here’s how to address the problem:

- Corrosion Prevention: Unstable pH levels can cause damage to system components over time.

- Biocide Effectiveness: Proper pH levels ensure biocides work as intended to control microbial growth.

- Scale Control: Monitoring pH helps minimize the risk of scaling, which can reduce system efficiency.

- Automated Monitoring: Utilize automated pH monitoring to track fluctuations in real-time.

- Acid/Base Dosing: Where needed, automated dosing systems can adjust pH to maintain optimal levels.

Strategy 4: Correct Critical Design and Operational Flaws

Even a mechanically sound tower can underperform due to design or operational oversights. A thorough triage of the system’s physical components is essential. This includes checking for issues like scaling, fouling, or improper airflow distribution, which can significantly impact efficiency.

Nozzle and Water Distribution

Uniform water distribution is paramount. Clogged or damaged nozzles create dry spots on the fill media, which are essentially dead zones for heat transfer. Inspect all nozzles to ensure they are clean, properly calibrated, and provide a consistent, even spray pattern across the entire fill surface.

Fill Media Inspection and Upgrade

The fill media plays a crucial role in air-water interaction, and its type greatly impacts performance. Ensuring the right fill for your local water quality is essential to avoid issues like biofouling and maintain efficiency. Here’s what to check and consider:

- Verify that the installed fill is suitable for your local water quality.

- If you experience chronic biofouling, the fill itself may be contributing to the problem.

- Upgrade to a high-density, anti-fouling fill to reduce biofouling.

- In challenging water conditions, switching from a film fill to a splash fill can provide a more robust solution.

Mitigate Air Recirculation

The physical location of your cooling tower matters. If hot, saturated air exiting the top of the tower is drawn back into the air intakes, it artificially raises the entering WBT and cripples efficiency.

Assess the tower’s proximity to walls, buildings, or other obstructions. If recirculation is suspected, installing baffles or increasing the discharge air velocity can resolve the issue.

Achieve High-Performance Cooling in Any Climate

To maximize your cooling tower’s wet-bulb drop in a tropical climate, passive maintenance isn’t sufficient. You need an active, integrated optimization program that tackles mechanical, thermal, and chemical challenges together. This involves more than routine checks; it means optimizing airflow, mitigating recirculation, and implementing robust bio-control and water treatment strategies.

Investing in proactive optimization for your Tropical Climate Cooling Tower can yield significant returns, including major chiller energy savings, enhanced system reliability, and longer equipment life.

Ready to unlock your system’s true potential and stay ahead in your industry? At ICST, we specialize in innovative solutions designed to optimize performance and drive results. Visit our website to discover how our expertise can help you achieve your goals and lead the way in your field.

Frequently Asked Questions

How do I increase airflow in my cooling tower?

Optimizing fan pitch, tuning VSD settings, and reducing static pressure losses help boost airflow. Regularly checking drift eliminators and louvers also prevents hidden airflow blockages.

How does biofilm reduce cooling efficiency?

Biofilm acts as an insulation layer on fill media, slowing heat transfer and increasing approach temperature. Removing it through biocide rotation and filtration instantly improves performance.

How does the monsoon season impact cooling towers?

Humidity increases wet-bulb temperature, reducing cooling capacity. Automated TDS control, pH stabilization, and optimized fan operation help maintain performance during monsoon months.

What is the best way to control scale in cooling towers?

Consistent chemical dosing, proper blowdown control, and routine descaling. Monitoring inhibitors and phosphate levels ensures scale doesn’t build on fill or heat-exchange areas.

What is a good approach temperature for a cooling tower?

A cooling tower’s approach temperature usually falls between 5–10°F (around 2.8–5.6°C). Modern high-efficiency systems are often designed to achieve an approach close to 5°F, as this range indicates strong thermal performance.