Are temperature spikes threatening your production lines, or do energy bills keep climbing no matter what you try? Imagine walking through a facility where every machine operates at peak efficiency, and cooling is not just a background system; it is the silent guardian of your profit and product quality. This is the reality for companies leveraging modern Industrial Cooling Applications.

Savvy facility managers and operations directors know these systems are not mere utilities; they are the backbone of consistent cooling, safeguarding sensitive components, and keeping operations efficient. From advanced fluid cycles to the intelligent orchestration of chillers, cooling towers, and air-cooled systems, the right industrial cooling solution turns energy costs into operational savings.

In this article, you will discover ten expert secrets that reveal how Industrial Cooling Applications can shift your cooling system from a simple cost to a powerful driver of efficiency and success.

Table of Contents

ToggleThe Experts, Their Types, and The Top 10 Secrets

To boost operational efficiency, production efficiency, and equipment efficiency, you must understand who the decision-makers are for cooling applications and how they maximize manufacturing sector outcomes.

The Insiders: Expert Types and Strategic Features

Key industry experts include:

- The Process Engineer: Focuses on precise temperature control to maintain ideal temperatures for stable environments and quality outcomes in industrial processes, such as chemical reactions and food processing.

- The Sustainability Officer: Tracks energy efficiency, water usage, and the facility’s progress towards sustainability goals through Power Usage Effectiveness (PUE) and Water Usage Effectiveness (WUE).

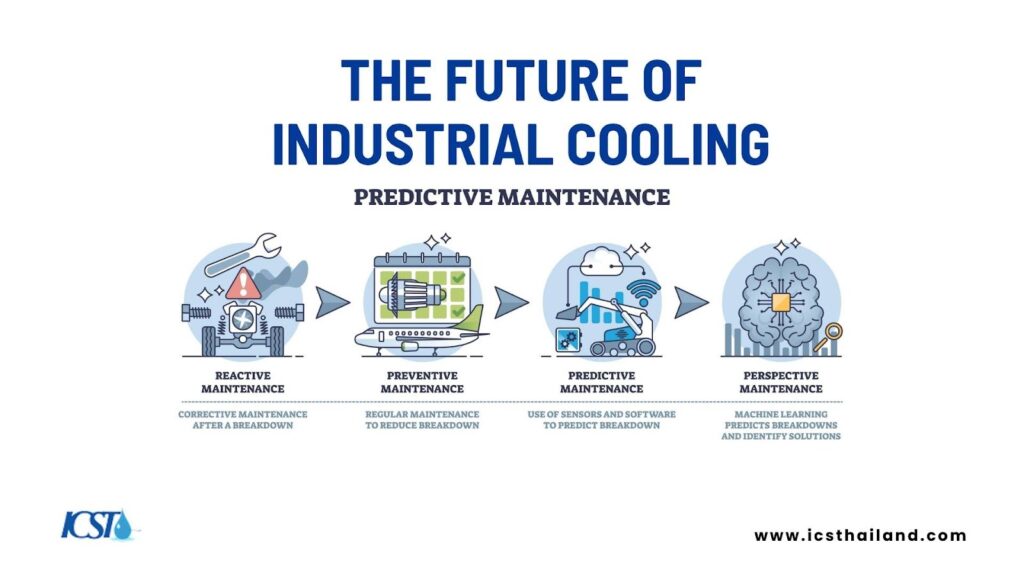

- The Reliability Manager: Uses predictive maintenance, IoT sensors, and data from modern cooling systems to protect equipment, optimize machinery health, and lower operational costs.

Modern cooling systems incorporate Variable Speed Drives (VSDs), closed-loop fluid coolers, advanced chillers, and real-time IoT monitoring for efficient and robust performance.

The Top 10 Secrets Smart Experts Know

Unlock the hidden benefits of industrial cooling systems in many industrial processes with these proven strategies:

- The Closed-Loop Mandate: Avoid open-loop cooling towers for process water. Use glycol in a closed-loop industrial cooling system to remove dirt, prevent contamination, and extend equipment life for manufacturing and beverage production.

- The Adiabatic Tipping Point: Balance water evaporation and air cooling. Install hybrid or evaporative cooling systems that operate in dry mode most of the year, using water only on the hottest days for higher efficiency and lower water use.

- PUE is Obsolete: Move past PUE for industrial processes. Use Energy Efficiency Ratio (EER) as your KPI for chillers and compare all applications of industrial cooling systems accordingly.

- The Expansion Valve Trap: Digital or electronic expansion valves enhance precise control, keeping fluid at stable temperatures and preventing heat damage in pharmaceutical manufacturing and food and beverage production.

- Heat Recovery is Free Power: Install heat exchangers to capture and reuse excess heat from compressors, reducing energy costs for power generation and other cooling systems.

- The Predictive Sensor Test: Equip industrial cooling systems with vibration and acoustic sensors. This allows predictive maintenance, ensures production efficiency, and protects machinery in cold storage and food processing.

- Customer Lifetime Cooling: Calculate the Lifetime Value (LTV) of your cooling application, considering operational costs, energy savings, and the value of maintaining product quality and reducing downtime.

- The Water-Wasting Lie: In regions with limited water availability, air-cooled systems and water-cooled systems can replace traditional cooling towers, ensuring compliance and reducing reliance on water while still meeting cooling needs.

- The Refrigerant Time Bomb: Migrate to low-GWP refrigerants in all modern cooling systems to prevent regulatory issues and future-proof your industrial cooling application.

- The AI Command Center: Use AI, IoT, and data center-grade controls to dynamically balance loads, maintain stable environments, and optimize energy consumption in high cooling loads and production environments.

The Financial Betrayal: Exposing Hidden Costs & Maximizing ROI

Focusing on initial CapEx alone is a common mistake in industrial processes. Utilizing the right industrial cooling system reduces your Total Cost of Ownership (TCO) and unlocks greater operational efficiency, critical for the manufacturing sector and food and beverage industries.

Why You Need the Right Industrial Cooling System

The right solution slashes operational costs for energy, water, and maintenance. You achieve high efficiency, lower risk to components, and consistent cooling that preserves product quality and uptime.

Cost and Efficiency: A Head-to-Head Comparison

| Cost Factor | Legacy Cooling Tower/Chiller | Modern Adiabatic/Hybrid System | Savings & Strategic Advantage |

| Energy Consumption | High; compressor and inefficient system | Low; VSD, high efficiency, and optimized air | Up to 40% reduction in energy costs |

| Water Usage | High due to continuous evaporation | Intermittent, only peak need | Up to 95% less water consumption and improved WUE |

| Maintenance | Intensive, chemical treatment required | Predictive focus, simple cleaning | Fewer chemicals, streamlined maintenance, reduced downtime |

| Asset Risk | High; prone to contamination | Low; closed-loop, stable temperatures | Longer asset life and fewer unplanned shutdowns |

Common Mistakes to Avoid

- Sizing Errors: Over- or undersizing your industrial cooling system impacts process and equipment performance and increases operational costs.

- Neglecting Water Quality: Poor water quality wrecks heat exchangers, causes scale, and shortens machinery lifespan.

- Ignoring Insulation: Bad insulation results in loss of cooling, temperature swings, and inefficient processes.

Decoding the Future: Endless Possibilities

Modern cooling systems are evolving to meet new efficiency, regulatory, and sustainability standards. Facilities driven by energy efficiency and process control require flexible, scalable technologies.

Eco-Friendly Industrial Cooling Options

Hybrid and adiabatic systems are now the standard in food processing and other industries aiming for sustainability goals. Transitioning to low-GWP refrigerants is crucial for every application in industrial cooling systems.

The Future of Industrial Cooling: AI and IoT

AI, IoT, and advanced data analytics enable predictive maintenance, precise temperature control, and adaptive energy management. Heat recovery and smart integration ensure high cooling loads are met efficiently in data centers, cold storage, and manufacturing.

The Strategic Playbook: Requirements & Implementation

Implement the right cooling system for your process and industry. Consider operational environment, cooling needs, and system scalability.

Uses for Applications Industrial Cooling Systems

- Data Centers: Require low PUE, WUE, and optimal air cooling to handle excess heat from electrical systems.

- Pharmaceutical and Food & Beverage Production: Need sanitary, closed-loop chillers and evaporative cooling systems to maintain product quality and worker safety.

- Heavy Manufacturing: Demands robust cooling towers and systems for high cooling loads, consistent cooling, and protection of sensitive components.

Requirements and Strategies

- Confirm water availability and environmental conditions.

- Use expansion valves, BMS, and IoT devices for precise control.

- Analyze thermal load, refrigerant choice, CapEx vs. OpEx, and future scalability for the right fit.

How to Gain the Ultimate Advantage

Consult experts for TCO and ROI modeling for your applications of industrial cooling systems. Prioritize vital role systems that maximize equipment efficiency, foundational for operational success in demanding industries and environments.

Your Next Strategic Cooling Decision

Industrial cooling systems are crucial. The right cooling system delivers energy efficiency, stable temperatures, and ensures worker safety in all industrial process environments. You now have the keys to reducing operational costs and protecting your assets—optimize instead of just replacing equipment.

Contact our team today for a complimentary assessment. Benchmark your cooling needs and future-proof your facility with the best industrial cooling systems available at International Cooling Solutions.

Frequently Asked Questions

What are industrial cooling applications, and why are they important?

Industrial cooling applications involve systems designed to manage and remove excess heat from industrial processes, ensuring stable temperatures, protecting sensitive components, and maintaining production efficiency. They are vital for preventing overheating, ensuring worker safety, and optimizing operational efficiency.

What is the difference between air-cooled and water-cooled systems?

Air-cooled systems use air to dissipate heat, making them ideal for water-scarce regions. Water-cooled systems, on the other hand, use water for heat transfer, offering higher efficiency but requiring a reliable water supply.

How can I improve the energy efficiency of my cooling system?

To enhance energy efficiency, consider upgrading to modern cooling systems with Variable Speed Drives (VSDs), IoT sensors for real-time monitoring, and AI-driven dynamic load balancing. Regular maintenance and proper insulation also play a crucial role.

What are the benefits of using a closed-loop cooling system?

Closed-loop systems prevent contamination, scale buildup, and biological growth by isolating the cooling fluid from external elements. This ensures consistent cooling, reduces maintenance needs, and extends equipment life.

How do I choose the right industrial cooling system for my facility?

Selecting the right system depends on factors like your facility’s climate, thermal load, water availability, and operational goals. Consulting an expert to model Total Cost of Ownership (TCO) and Return on Investment (ROI) is essential for making an informed decision.