Cooling System Customer Satisfaction: 2026 Strategy Guide

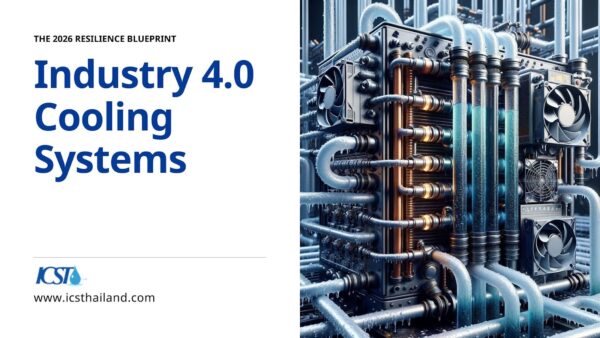

The industrial landscape of 2026 demands more than just basic temperature control. Cooling system customer satisfaction is no longer about merely fixing a broken fan or refilling a refrigerant. It is about predictive stewardship and transparency regarding Water Usage Effectiveness (WUE). Industrial partners now expect cooling systems to function as intelligent assets rather than passive…